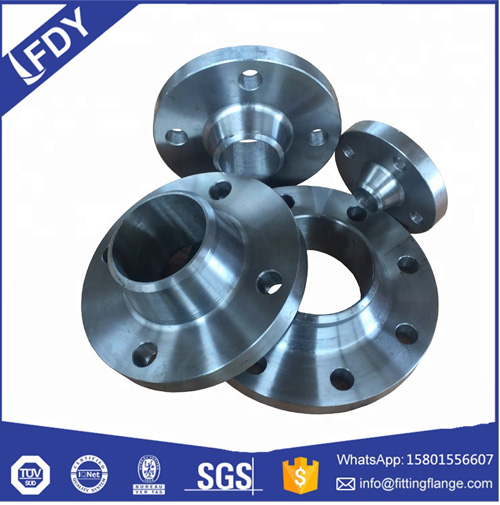

A lot of people should know about stainless steel flange, but in fact it is only an integral part. At the junction of a pipeline, use it to connect two components. These parts are very simple and easy to understand. We should learn how to maintain these components.

The welding current should not be too large, faster cooling is also a better operation method to prevent flange corrosion when welding stainless steel flange.

When using stainless steel flange, it is necessary to add appropriate stabilizing unit on the stainless steel flange. To make it stable to some extent, of course, there are many problems in the welding of stainless steel flange. For example, repeated heating corrosion is not easy to reduce to some extent, if you can pay attention to these things, give more attention and prevention. We can maintain them well and reduce losses.

Stainless steel flange is the most common plate-shaped part in pipeline engineering. Stainless steel flanges are used in pairs. In piping engineering, stainless steel flange is mainly used for piping connection, but please install all kinds of flange when connecting piping. Welding wire flange can be used for low pressure piping, and welding flange with pressure more than 4kg can be used. Sealing points can be added to the two stainless steel flanges, and then the sealing points can be tightened by bolts.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: