Carbon steel flanges are commonly used in a variety of industrial applications due to their strength, durability, and cost-effectiveness. They are especially popular in industries such as oil and gas, chemical processing, and water treatment. However, how do carbon steel flanges compare to other flange materials such as stainless steel, alloy steel, and brass?

Stainless steel flanges are another popular choice in industrial applications because of their corrosion resistance and aesthetic appeal. While stainless steel flanges may be more expensive than carbon steel flanges, they offer superior resistance to rust and staining, making them ideal for use in corrosive environments. Stainless steel flanges are also easy to clean and maintain, which can help extend their lifespan compared to carbon steel flanges.

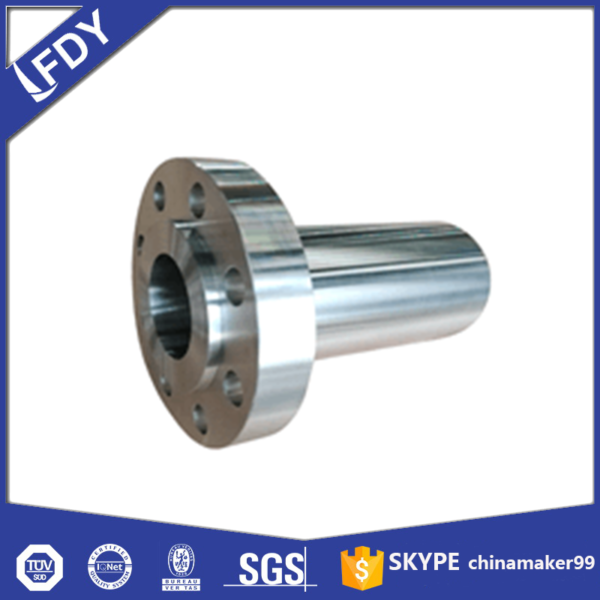

Alloy steel flanges are a type of steel that contains additives such as chromium, molybdenum, or nickel to improve their mechanical properties. Alloy steel flanges are often used in high-temperature and high-pressure applications where strength and toughness are critical. While alloy steel flanges are more expensive than carbon steel flanges, they offer superior strength, hardness, and resistance to wear and tear. Alloy steel flanges are also resistant to oxidation and corrosion, making them suitable for use in harsh environments.

In terms of performance, carbon steel flanges offer good strength, toughness, and weldability, making them suitable for a wide range of industrial applications. They are also widely available and cost-effective, making them a popular choice for budget-conscious projects. However, carbon steel flanges may be susceptible to corrosion and oxidation, especially in high-temperature and corrosive environments. In such cases, stainless steel or alloy steel flanges may be a better choice due to their superior corrosion resistance and mechanical properties.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: