Alloy steel flanges are indeed a viable option for various industrial needs. They offer numerous advantages over other types of flanges, making them a popular choice in many industries. In this article, we will discuss the benefits and applications of alloy steel flanges, as well as their potential limitations.

One of the key advantages of alloy steel flanges is their exceptional strength and durability. Alloy steel is made by adding various alloying elements, such as chromium, nickel, molybdenum, or vanadium, to carbon steel. This enhances its mechanical properties and makes it more resistant to corrosion, high temperatures, and wear. As a result, alloy steel flanges are capable of withstanding heavy loads and harsh operating conditions, making them ideal for industrial applications where strength and reliability are critical.

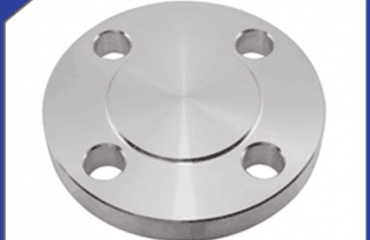

Another advantage of alloy steel flanges is their versatility. They are available in a wide range of sizes, pressure ratings, and types, including weld neck, slip-on, threaded, socket weld, and blind flanges. This allows them to be used in diverse industries, including oil and gas, petrochemical, power generation, chemical, and water treatment. Whether you need a flange for a high-pressure pipeline, a corrosive environment, or a specific temperature range, alloy steel flanges can be customized to meet your requirements.

Furthermore, alloy steel flanges have excellent weldability and machinability. This means they can be easily fabricated and assembled into complex structures or piping systems. The weldability of alloy steel allows for the creation of strong and leak-resistant joints, ensuring the integrity of the overall system. Additionally, their machinability allows for precise cutting, drilling, and threading, making them highly adaptable to different manufacturing processes.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: