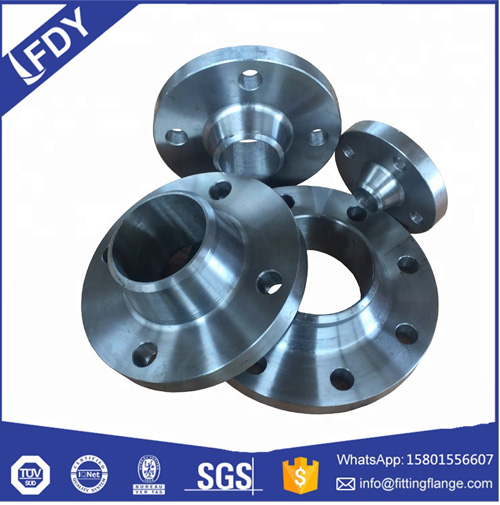

Alloy flanges refer to flanges made of various alloy materials such as stainless steel, carbon steel, and nickel alloys. Compared with traditional flanges, alloy flanges have many advantages. This article will introduce the advantages of alloy flanges in detail.

- Corrosion-resistant

Alloy flanges are made of materials with high corrosion resistance, which makes them ideal for use in harsh environments. They can withstand exposure to corrosive chemicals, acids, and bases without suffering any damage, which means they have a longer lifespan and require less maintenance.

- Heat-resistant

Alloy flanges are also highly heat-resistant, making them suitable for use in high-temperature environments. They can withstand extreme heat without losing their structural integrity or mechanical properties, which makes them ideal for use in high-pressure steam systems, boilers, and other high-temperature applications.

- High strength and durability

Alloy flanges are made of materials with high strength and durability, which makes them ideal for use in applications that require high reliability and performance. They are resistant to fatigue, stress, and wear, which means they can withstand high loads and pressures without suffering damage or failures.

- Versatility

Alloy flanges are available in a wide range of sizes, shapes, and grades, which makes them suitable for use in a variety of applications. They can be easily customized to meet the specific requirements of different applications, which means they can be used in a wide range of industries, including petrochemical, oil and gas, power generation, and water treatment.

- Compatibility

Alloy flanges are designed to be compatible with a wide range of piping and fitting systems, which makes them easy to install and connect. They can be attached to pipes or fittings of different sizes and types, which means they can be used with a variety of piping and fitting systems.

- Cost-effective

Alloy flanges are more cost-effective in the long run compared to traditional flanges, as they require less maintenance and have a longer lifespan. They are also more resistant to corrosion, heat and fatigue, which means they can withstand harsh environments and reduce the risk of failures, downtime, and repairs.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: