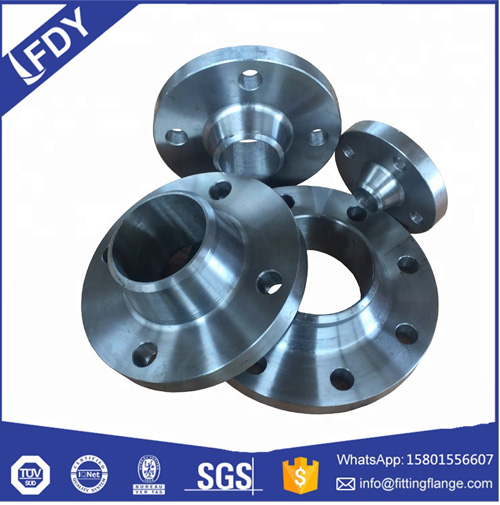

Flange is also called flange plate or flange. Flange is a part connected between pipes, which is used for the connection between the ends of pipes. It is also used for the connection between the importer and exporter of equipment and for the connection between two equipment. In practical use, the traditional flange not only runs safely, but also has limited service life due to poor corrosion resistance. The appearance of new alloy flange improves the anti-corrosion ability of flange to a great extent. It is generally used to connect pipes conveying special materials. Harbin alloy steel flange is one of the alloy flanges. Because it can work in various harsh environments such as high temperature, high pressure and strong corrosion, the effect of pipeline connection is effectively improved.

The application of alloy steel flange material is more in line with the use requirements of modern society, and has greater development space because of the demand. It has been widely used since its inception. Harbin alloy steel flange material is suitable for the installation and use of various oxidation and reduction industries. Alloy steel flange also contains a large number of lettering elements, which can still maintain its chemical properties when corroded by chloride ion. There is also corrosion resistance. The upgraded products have corrosion resistance and thermal performance. It has excellent performance, high strength and good oxidation resistance. It is easy to process in the mixed acid medium with the same strong oxidation. High temperature materials can be divided into superalloys, nickel base superalloys and cobalt base superalloys. According to the preparation process, it can be divided into deformed superalloy, cast superalloy and powder metallurgy superalloy.

In addition, with the passage of time, foreign demand will tend to be strong, so prices have strong support. However, after the rectification news came out, the price changed to a certain extent, and the market sentiment of alloy steel flange price was slightly unstable. The strict iron and steel enterprises should improve the steel output per unit area as much as possible. With the narrow rise in the market price of finished products, the decline of scrap steel slowed down, and some regions stopped falling and rebounded.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: