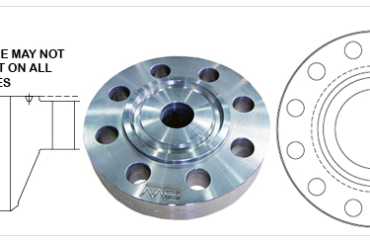

Special concave circular flanges are a versatile and innovative option for various applications in engineering and manufacturing. These unique flanges have a concave shape, which offers several advantages over traditional flat flanges. In this article, we will explore the benefits of special concave circular flanges and help you determine if they are the right choice for your specific needs.

One of the primary advantages of special concave circular flanges is their ability to distribute stress and pressure more evenly across a joint. The concave shape creates a larger contact area between the flange and the mating surface, which helps to reduce the risk of leaks or failures due to uneven pressure distribution. This can be particularly important in high-pressure applications where uniform stress distribution is crucial for the integrity of the joint.

Another key benefit of concave circular flanges is their ability to compensate for minor misalignments or surface irregularities in the mating components. The concave shape allows the flange to conform to the shape of the mating surface, providing a tighter seal and reducing the likelihood of leaks or other issues. This can be especially helpful in applications where precise alignment is difficult to achieve, such as in piping systems or machinery with multiple moving parts.

Special concave circular flanges are also known for their superior sealing properties compared to flat flanges. The larger contact area and more uniform stress distribution created by the concave shape help to create a more reliable and durable seal, even under challenging conditions. This can be an important consideration in applications where leaks or failures could have serious consequences, such as in high-temperature or corrosive environments.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: