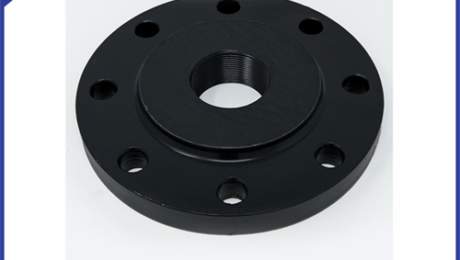

Specific Production Method of Carbon Steel Flange

Monday, 09 September 2024

Heating temperature is a key index in heat treatment of large diameter flange and other flange fittings. The selection and control of heating temperature involves the quality of heat treatment and the final product quality, therefore, how to choose the proper heating mode and how to control the heating temperature in the heat treatment process

- Published in INDUSTRY NEWS

No Comments

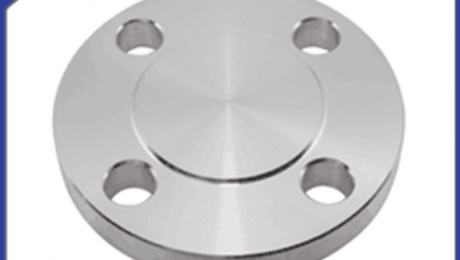

Are Blind Flanges the Best Solution for Your Pipeline System?

Monday, 02 September 2024

Blind flanges are used in pipeline systems for a variety of purposes, including blocking off a section of pipeline, testing the flow of fluid, and maintaining the integrity of the system during maintenance or repair. They are basically solid discs that are used to block off a section of pipe or to create a dead

- Published in INDUSTRY NEWS

The difference of flange and blind flange

Monday, 02 September 2024

1. The characteristics of the two are different The normal name of blind flange is flange cover, and it is also called blind flange or closed pipe. This is a kind of flange without hole in the middle, which is mainly used for the front end of pipe seal. It is used for sealing port,

- Published in INDUSTRY NEWS

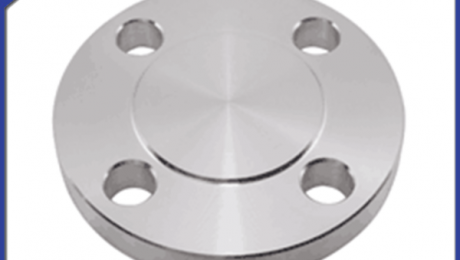

Why is Stainless Steel Flange Used in Various Industries?

Monday, 19 August 2024

Stainless steel flanges are commonly used in various industries for a number of reasons. One of the main advantages of using stainless steel flanges is their durability and resistance to corrosion. Stainless steel is a material that is highly resistant to rust and corrosion, making it a great choice for applications where exposure to moisture

- Published in INDUSTRY NEWS

Maintenance method of stainless steel flange

Monday, 19 August 2024

A lot of people should know about stainless steel flange, but in fact it is only an integral part. At the junction of a pipeline, use it to connect two components. These parts are very simple and easy to understand. We should learn how to maintain these components. The welding current should not be too large,

- Published in INDUSTRY NEWS

The Impact of Pipe Fitting Regulations on Industry Standards

Monday, 12 August 2024

Pipe fitting regulations play a critical role in ensuring the safety, efficiency, and quality of the products and services offered in the industry. These regulations are put in place to standardize practices and procedures, prevent accidents and injuries, and protect the environment. One of the key impacts of pipe fitting regulations on industry standards is

- Published in INDUSTRY NEWS

The Advantages and Disadvantages of Stainless Steel Pipe Fittings

Monday, 12 August 2024

Advantages of stainless steel pipe fittings: such as stainless steel elbow, tee and so on: Stainless steel pipe fittings Because of easy cleaning, beautiful appearance, not rusty and widely used in various industries. The disadvantages of stainless steel pipe fittings are as follows: Differential heat transfer: Except for bonded aluminum or copper base, thermal conductivity is very poor.

- Published in INDUSTRY NEWS

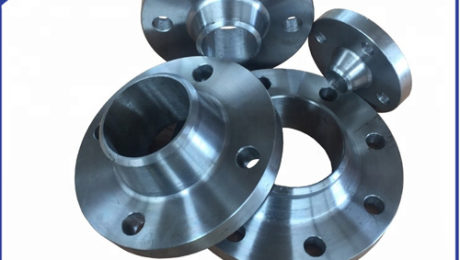

Top Benefits of Using Alloy Steel Flange in Various Industries

Monday, 05 August 2024

Alloy steel flanges are widely used in various industries due to their numerous benefits and properties. These flanges are made from a combination of multiple metals, including carbon, manganese, silicon, nickel, and chromium, which give them superior strength, durability, and corrosion resistance. Alloy steel flanges have a higher tensile strength and yield strength compared to

- Published in INDUSTRY NEWS

Application and development of alloy steel flange

Monday, 05 August 2024

Flange is also called flange plate or flange. Flange is a part connected between pipes, which is used for the connection between the ends of pipes. It is also used for the connection between the importer and exporter of equipment and for the connection between two equipment. In practical use, the traditional flange not only

- Published in INDUSTRY NEWS

What Makes Carbon Steel Flange Superior?

Monday, 29 July 2024

Carbon steel flanges are considered to be superior due to several key factors that distinguish them from other types of flanges. One of the main reasons why carbon steel flanges are preferred is their durability. Carbon steel is known for its strength and resilience, making it ideal for high-pressure and high-temperature applications. Carbon steel flanges

- Published in CLIENTS STORY

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: