The welding flange is usually made of forgings or forged rolling process. In industrial pipelines, flange connections are widely used. But open section elbow bend pipe all line, only consider the cost, bend tube cold bend can, elbow need hot simmer, of course, elbow cost is high. The industrial structure of carbon steel flange, including product structure, technical structure, import and export structure and so on, has problems in different degrees. The local strain induced by weld shrinkage often reaches several times of the yield point strain, and the strain caused by the load is much larger. Residual stresses caused by uneven cooling.

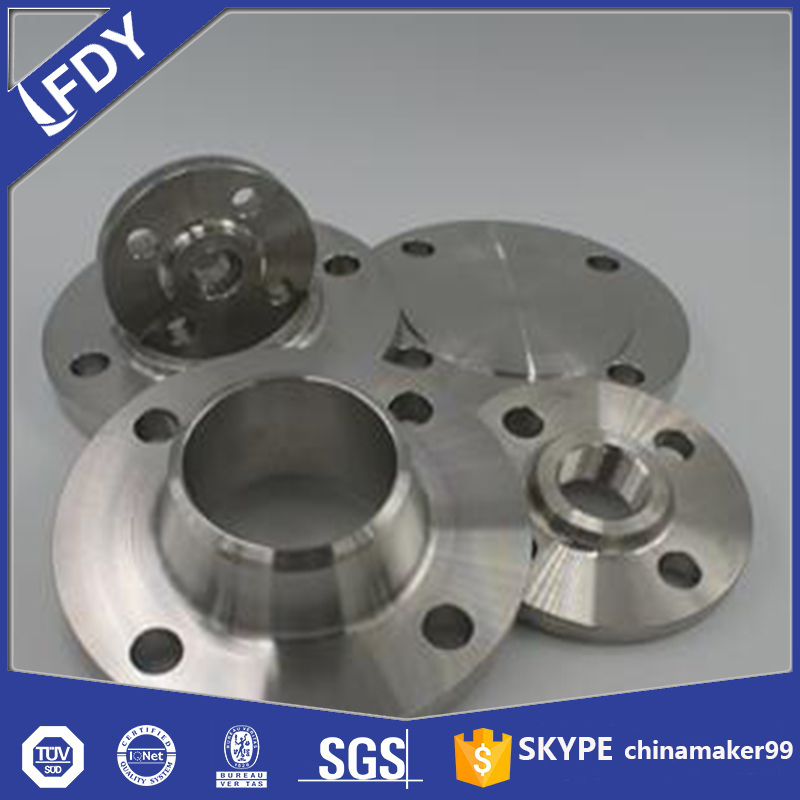

The bending and torsion of the force model of a cantilever beam with a groove structure should be calibrated and its deflection and rotation angle should be verified. For the use of seamless pipe manufacturing tee, the current commonly used process has hydraulic bulging and hot forming two. Stainless steel flange manufacturers to rust from the low pressure asbestos pad, high-pressure asbestos pad to metal mats are there. Carbon steel Elbow After the completion of welding according to the requirements of the product skills of the corresponding inspection of the weld, where the lack of compliance with the skills required to allow the shortcomings, need to be repaired in a timely manner (such as serious unqualified failure to repair the direct abandonment). The welding flange is used for the connection of the middle and high pressure pipe, the flange of butt welding is at least 2.5, the welding is used to reduce the stress concentration, the general weld flange is also called the nipple flange. Large-caliber flange manufacturers are also the same, now products from the work, or from the size of the past product is almost, this is also undeniable reality, because the market state is so, this situation for the flange manufacturers market, and even the entire industrial market is bad, hope to engage in the production of flange manufacturers and users to work together to improve this unsatisfactory situation.Roller processing method. The fatigue life of the slip on flange is about one-third of the weld neck flange, the performance of the internal pressure is the same as that of the slip on flange, while the slip on flange is cheap and the flange of the thread is connected.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: