Carbon steel pipe fittings are connected in a way that is very much, according to the specific situation, to choose the way of connection, some require the quality of the pipe better, thicker, more anti-corrosion capacity, such as the transportation of oil, natural gas pipelines, once the leakage is very serious, carbon steel pipe parts In this respect quality is very good.

First, learn the basics of pipe fittings

Generally only if the use of pipe as raw material, further processing products are pipe fittings, pipe fittings is the link and bridge, without them, many pipes are no way to use, carbon steel pipe parts of the neck is very high, its ability to withstand a lot of improvement, it is more than welding pipe fittings have a lot of advantages, such as his workload, small energy consumption and so on.

Second, the stiffness of carbon steel pipe parts is very large

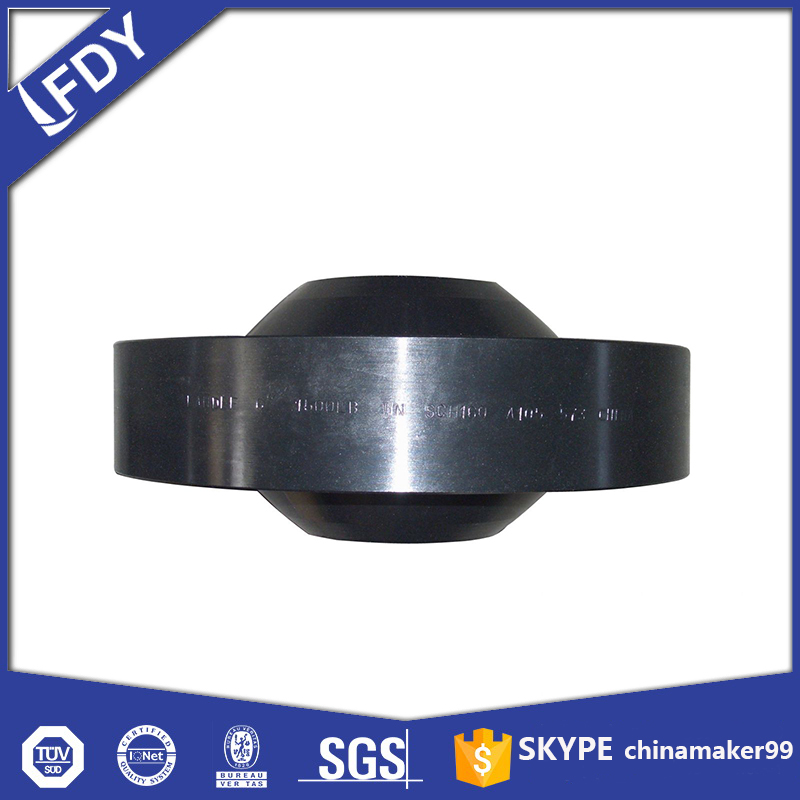

In many industries, carbon steel fittings are commonly used fasteners, is widely used, carbon steel pipe stiffness is very large, carbon steel pipe parts have two methods of connection, one is a rigid flange connection, a flexible flange connection, carbon steel flange has a great bearing capacity, its stiffness is also very large.

Third, the advantages of flexible flange

In the construction, in order to avoid a large number of welding, so that the installation and fabrication of flange more convenient, can not be stiffened plate, but with a flexible flange, its appearance is beautiful and concise, installation and production is very convenient, but also very time-saving, but because it is not the strength of the bolt to bear a very uniform, so it can not withstand great pressure, its stiffness is relatively small.

Fourth, technology and testing of insulating joints

Its quality is very good, the life is very long, the intensity is also very high, in oil, steam and many other anti-corrosion protection, it is used in the form of extrusion welding, it is the insulation and sealing material fixed in the sleeve, assembled after the completion of the corresponding position, under some pressure test, it can be maintained intact.

Fifth, its scope of use

It is commonly used in the connection of pipelines such as oil and natural gas, these transmission pipelines are very afraid of corrosion, the requirements of the quality of carbon steel pipe pieces are very high, to meet the requirements of different users, to develop the material of pipe fittings, such as carbon steel pipe pieces, but also can use different pipe mixing connection, such as flange connection, threaded connection.

To do a good job of testing and safeguarding the performance of insulation voltage, only in time to detect problems, to be able to better deal with, can use potential method to test, can also use the trillion-European table method to test, to fine-measure its performance, in which the material of carbon steel pipe piece is very good.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: