What are the mechanical properties of dual phase steel flange

Wednesday, 11 May 2022

The existence of dual phase steel flange restricts the growth of grains between dual phases. Dual phase stainless steel maintains fine grains, and the total area of grain boundary of dual phase stainless steel is larger than that of single-phase steel. Therefore, dual phase stainless steel has high strength, especially yield strength, ensuring certain plasticity

- Published in INDUSTRY NEWS

No Comments

Anti corrosion method of pipeline flange

Friday, 06 May 2022

I. paint maintenance solutions Maintenance paint is a hard film that can be directly bonded to the substrate, generally epoxy or polyurethane coatings. There are many edges and edges in the China flange, and the edge will become thinner with the service time and the action of corrosive medium. It is difficult for the conventional coating

- Published in INDUSTRY NEWS

What should be paid attention to when installing non-standard flange?

Tuesday, 26 April 2022

Non standard flange refers to the parts used when connecting pipes, pipes and valves. There are holes and bolts on it to tightly connect the two flanges. Non standard flange is widely used in many industries because of its excellent performance. It is one of the mechanical parts widely used in industrial equipment and production.

- Published in INDUSTRY NEWS

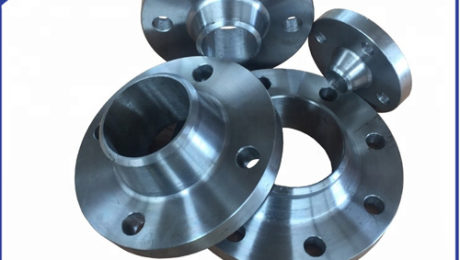

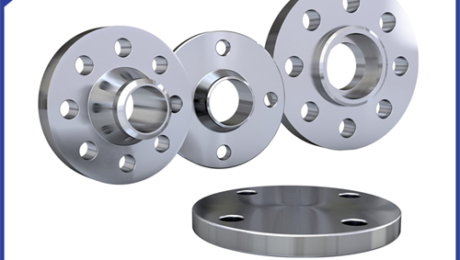

Specific classification of flanges

Wednesday, 20 April 2022

A. Flange types are divided according to national standards: integral flange, threaded flange, butt welding flange, flat welding flange with neck, socket welding flange with neck, butt welding ring with neck loose flange, plate flat welding flange, flat welding ring plate loose flange, flat welding ring plate loose flange, flanging ring plate loose flange and

- Published in INDUSTRY NEWS

What is a flange gasket

Wednesday, 20 April 2022

Flange gasket is a kind of ring made of materials that can produce plastic deformation and have certain strength. It is resistant to high temperature, high pressure and corrosion, and has good compression rate and rebound rate. Most gaskets are cut from non-metallic plates, or asbestos rubber plates, asbestos plates, PTFE plates and polyethylene plates

- Published in INDUSTRY NEWS

What are the mechanical properties of duplex steel flange

Wednesday, 13 April 2022

The existence of dual phase steel flange restricts the growth of grains between dual phases. Dual phase stainless steel maintains fine grains, and the total area of grain boundary of dual phase stainless steel is larger than that of single-phase steel. Therefore, dual phase stainless steel has high strength, especially yield strength, ensuring certain plasticity

- Published in INDUSTRY NEWS

Some problems caused by flange connection

Thursday, 07 April 2022

With the rapid development of social economy, industrial leakage has been perplexing many industrial managers. Industrial leakage is due to problems in the pipeline system, and the vast majority of pipeline system problems are due to problems in an important part of the pipeline system – flange. Flange is a part connected between shafts. It

- Published in INDUSTRY NEWS

Welding technology of high neck flange

Wednesday, 30 March 2022

Welding technology: 1. Tack welding Tack welding must be carried out by welders with corresponding qualification certificates. The surface and both sides of the base metal near the weld shall be uniform and smooth without burr, crack, oxide scale, rust, grease, water and other impurities. The thickness of the positioned welding seam shall not be

- Published in INDUSTRY NEWS

Brief introduction of high neck flange

Wednesday, 30 March 2022

Neck flange, also known as long neck flange and neck flange, is a disc-shaped part, which is mainly used to realize the connection between pipelines. It has been widely used in petrochemical, urban water supply and power system. In recent years, with the planning and construction of UHV transmission line project of State Grid, the

- Published in INDUSTRY NEWS

Large flanges have relatively large load bearing capacity and are not easily deformed in engineering

Wednesday, 23 March 2022

Generally, large flanges have relatively large load bearing capacity and are not easily deformed in engineering. The key problem is thickness. The inside and outside diameters of large flanges are not a problem, but the thickness of flanges is the most difficult to process. Large flanges are easy to deform if they are too thin.

- Published in INDUSTRY NEWS

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: