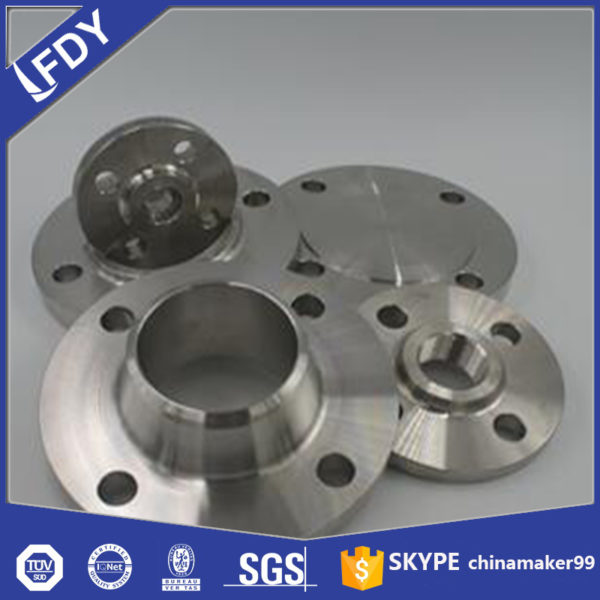

The stainless steel flange is easy to make, simple to manufacture, low in cost and widely used, but the rigidity is poor, so it can not be used in the chemical process piping system with the requirement of supply and demand, flammable, explosive and high vacuum degree, and the high and extreme harm situation. The sealing type has a plane and a sudden face.

Stainless Steel Flange Features: Simple structure, small size, light weight, tight and reliable, the current ball valve sealing surface materials widely used plastic, good sealing, in the vacuum system has been widely used, easy to repair, the ball valve structure is simple, sealing ring is generally active, disassembly and replacement is more convenient; in full or closed, the ball and seat sealing surface and media isolation.

Stainless Steel Flange film is not produced corrosion, pitting, corrosion or wear, is the construction of metal materials in one of the highest strength. Because the stainless steel has good corrosion resistance, it can make the structural parts permanently maintain the integrity of the engineering design. Chromium-containing stainless steel flange film also set mechanical strength and high extensibility in a, easy parts of the processing and manufacturing, can be satisfied with architects and structural designers need. All metals react with oxygen in the atmosphere, forming an oxide film on the surface.

In the maintenance of stainless steel flange is necessary to pay attention to some problems: long-time use of stainless steel flange should be scheduled to check, often on the surface of the exposed processing should be kept clean, clean dirt, neatly stored in the room ventilated dry place, is strictly prohibited to heap or open storage. Always keep the stainless steel flange dry and ventilated, keep the clean and tidy, according to the accurate storage method.

Installation, the stainless steel flange can be connected directly to the tube on the road, according to the location used to install. Under normal circumstances, can be installed in the pipeline at any location, but to facilitate the operation of the inspection, pay attention to the cut-off stainless steel flange medium flow should be the vertical disc below the upper, stainless steel flange can only be installed horizontally. Stainless steel flange in the installation should pay attention to the tightness, to prevent leakage phenomenon, affect the normal operation of the pipeline.

In order to prolong the service life of the stainless steel flange tap, to improve the quality of thread processing, we should pay attention to some matters needing attention when processing and production: the surface of the tap thread is coated with titanium nitride, which can remarkably improve the abrasion resistance, heat resistance and lubricity of the tap. But it should be noted, such as the shovel back too large, it is easy to produce the phenomenon that the chip plugs into the back corner of the tap in the retract, and the thread finish of the tapping is not good; enlarge the front corner of the tap properly, but notice that the front corner of the tap is too large, and it is easy to cause the tap to collapse and the tapping of the

Because the stainless steel has good corrosion resistance, it can make the structural parts permanently maintain the integrity of the engineering design. Stainless steel flanges do not produce corrosion, pitting, rust or abrasion. Chromium-containing stainless steel flange is also set mechanical strength and high extensibility in a, easy parts of the processing and manufacturing, can be satisfied with architects and structural designers need. All metals react with oxygen in the atmosphere, forming an oxide film on the surface. If a hole is formed, it can be plated with paint or oxidation-resistant metals to ensure the surface of the carbon steel, but, as is known, this protection is only a thin film.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: