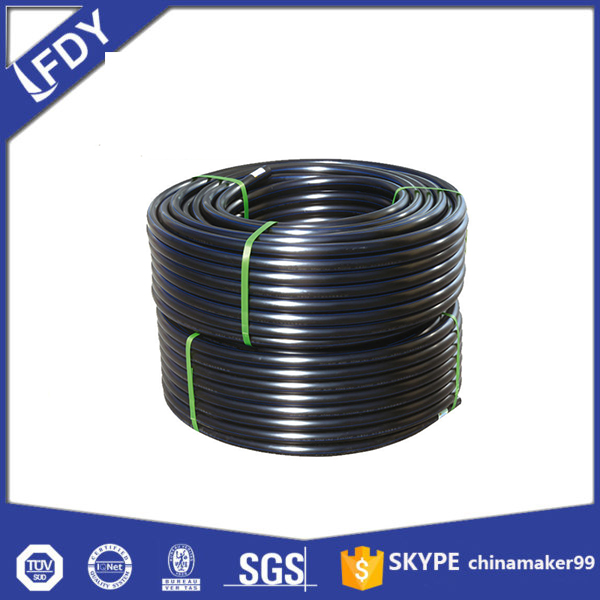

A revolutionary progress has taken place in the field of pipeline in this century, namely “replacing steel with plastic”. With the rapid progress of polymer materials science and technology, the deepening of the development and utilization of plastic pipes and the continuous improvement of production technology, plastic pipes show their excellent performance incisively and vividly. Today, plastic pipes are no longer mistaken as “cheap substitutes” for metal pipes. In this revolution, polyethylene pipes are favored and increasingly shine. They are widely used in gas transportation, water supply, sewage discharge, agricultural irrigation, mine fine particle solid transportation, oil field, chemical industry, post and telecommunications, especially in gas transportation.

HDPE is a thermoplastic polyolefin produced by ethylene copolymerization. Although HDPE was introduced in 1956, this plastic has not yet reached the mature level. This general-purpose material is still developing its new uses and markets.

China’s domestic producers of high-density polyethylene (high-density polyethylene here does not include high-density polyethylene produced by full density polyethylene unit) include PetroChina, Sinopec and CNOOC. By the end of 2006, there were 4 sets of high-density polyethylene units belonging to PetroChina, namely Lanzhou Petrochemical high-density polyethylene unit, Daqing Petrochemical high-density polyethylene unit Liaoyang Petrochemical high density polyethylene plant, Jilin Petrochemical high density polyethylene plant.

HDPE is usually manufactured by Ziegler Natta polymerization, which is characterized by no branched chain on the molecular chain, so the molecular chain arrangement is regular and has high density. In this process, ethylene is used as raw material and oxygen or organic peroxide as initiator in tubular or kettle low-pressure reactor.

HDPE is an environmentally friendly material, which can be recycled after heating to the melting point. It should be noted that plastic raw materials can be divided into two categories: “thermoplastic” and “thermosetting”. Thermosetting becomes solidified after heating to a certain temperature. Even if it continues to heat, its state cannot be changed. Therefore, products with environmental protection problems are “thermosetting” products (such as tires), not “Thermoplastic” products (such as plastic pallet note: pallet is called “plywood” in Hong Kong and Macao), so not all “plastics” are environmentally friendly.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: