Loose sleeve flange: Often used for medium temperature and pressure are not high, and medium corrosive situation. The hydraulic bulging process of tee can be formed at one time, the production efficiency is higher, and the head and shoulder wall thickness of tee are increased.

After heating the blanks in the mold in advance and then forge to make it slowly forming this method also belongs to die forging short die forging, the general die-forging of the flange crystal microstructure of high strength of course, the price is relatively expensive.

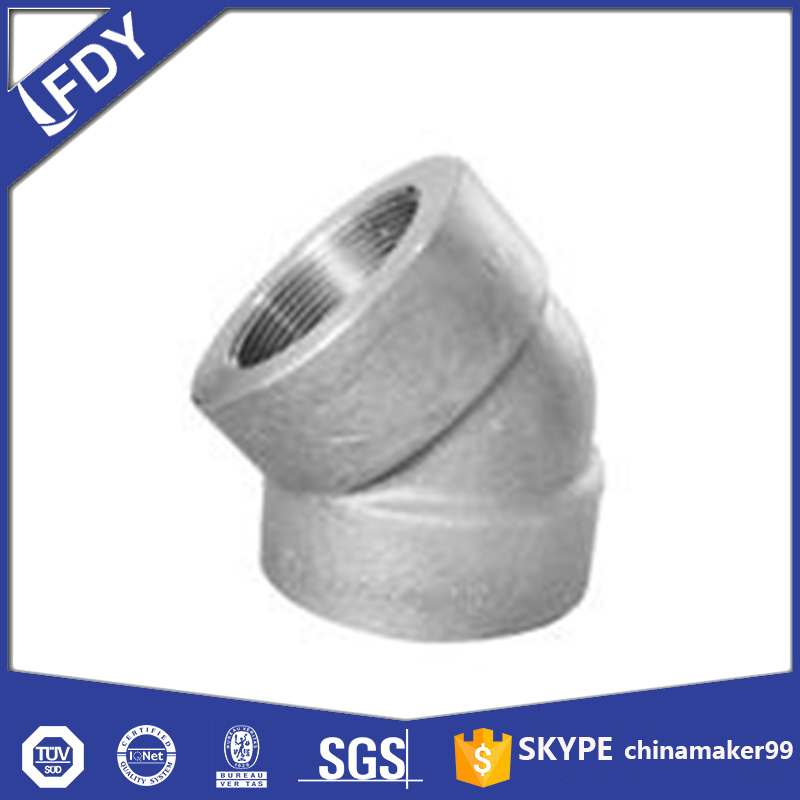

The stainless steel elbow produced by our company is simple to be divided into two kinds: hot-push forming and stamping forming. Because of the forging process of forged flange piece, the internal structure of flanges is compact and can be used in medium and high pressure condition. Steel plate flange plate is only suitable for low pressure working condition

Elbow quality and quality of the consumer’s use has a huge impact, not only related to the use of the process of reliability and security, but also directly affect the installation costs and maintenance costs. At the moment the tensile strength reaches a peak of 203. If the pipe to prevent the appearance of welding blowhole, welding parts such as rust, oil, etc. must be clean. Carbon steel elbow electrode has good corrosion resistance and oxidation resistance, widely used in chemical industry, fertilizer, petroleum, medical machinery manufacturing. The use of rolling DAFA orchids is widely used according to different characteristics, in mild conditions above the medium, such as suit circulating water low, compressed air purification, the advantages of cheap price.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: