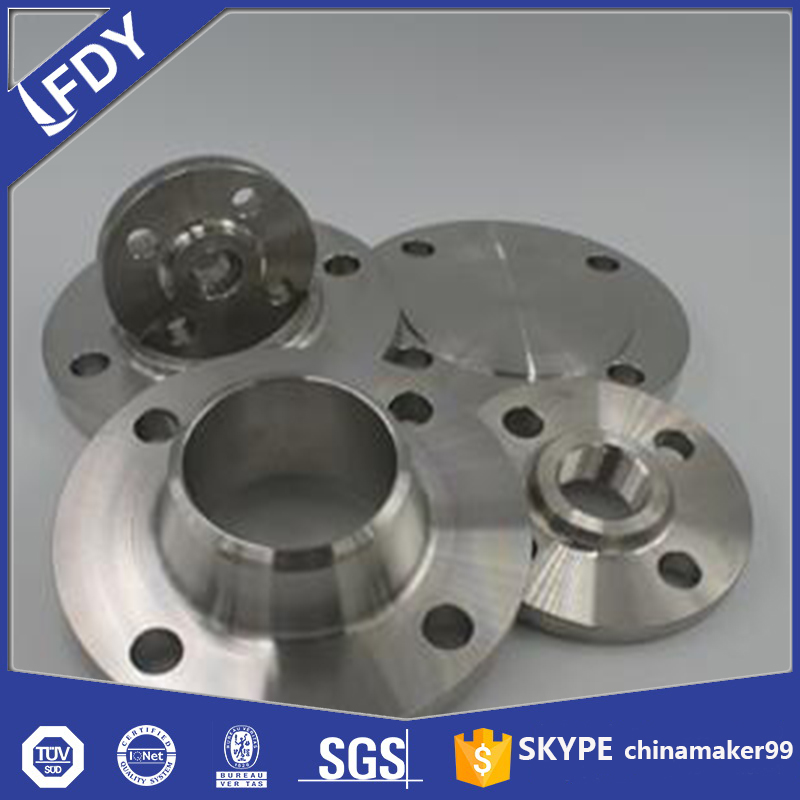

Stainless steel flanges are an important component used in various industries, such as oil and gas, chemical, pharmaceutical, and food processing. They are used to connect or join pipes, valves, and other equipment in a piping system. Flanges provide a secure and leak-proof connection, ensuring the integrity of the system.

Stainless steel flanges come in different classifications, each suited for specific applications and environments. Let’s explore some of the common classifications of stainless steel flanges.

Austenitic Stainless Steel Flanges: Austenitic stainless steel flanges are the most common type used in various industries. They are known for their excellent corrosion resistance, high strength, and good weldability. These flanges contain high amounts of chromium and nickel, which provide the corrosion resistance properties. Austenitic stainless steel flanges are suitable for a wide range of applications, including water treatment, food processing, and chemical processing.

Martensitic Stainless Steel Flanges: Martensitic stainless steel flanges are characterized by their high strength and hardness. They have a lower corrosion resistance compared to austenitic stainless steel flanges. Martensitic flanges are commonly used in applications where high mechanical strength and wear resistance are required. These flanges are used in industries such as oil and gas, petrochemical, and power generation.

Ferritic Stainless Steel Flanges: Ferritic stainless steel flanges are known for their high resistance to stress corrosion cracking. They have a lower content of chromium compared to austenitic stainless steel flanges, but higher amounts of other alloying elements such as molybdenum. Ferritic flanges are often used in applications where resistance to chloride-induced stress corrosion cracking is required, such as seawater environments or high chloride content environments.

Duplex Stainless Steel Flanges: Duplex stainless steel flanges are a combination of austenitic and ferritic stainless steels. They offer a good balance of strength and corrosion resistance. Duplex flanges have a higher chromium content than ferritic flanges and a lower nickel content than austenitic flanges. These flanges are commonly used in applications where high strength, corrosion resistance, and resistance to chloride-induced stress corrosion cracking are required, such as offshore oil and gas platforms and chemical processing equipment.

Stainless steel flanges come in various classifications suited for specific applications and environments. Austenitic stainless steel flanges are the most common type, offering excellent corrosion resistance. Martensitic, ferritic, duplex, and super duplex stainless steel flanges provide varying levels of strength and corrosion resistance, making them suitable for different industrial applications. Selecting the right classification of stainless steel flanges is crucial to ensure the performance and longevity of the piping system.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: