Butt welded fittings play a crucial role in various piping systems, providing reliable connections and facilitating the flow of fluids and gases. There are several different types of butt welded fittings available in the market, each with its own unique characteristics and applications.

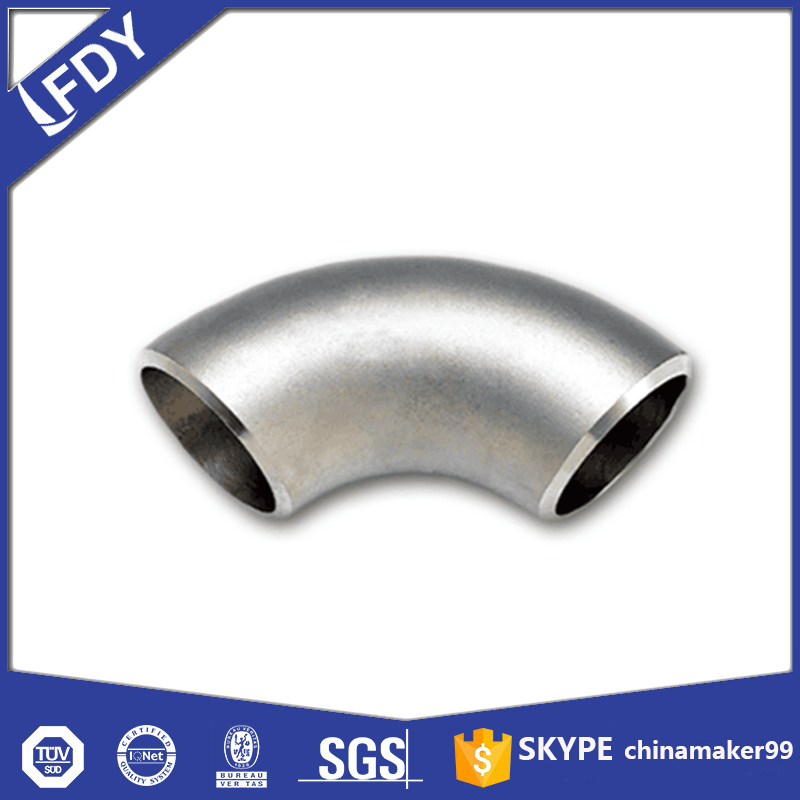

One common type is the elbow, which allows for a change in the direction of the pipe. Elbows come in different angles, such as 90-degree and 45-degree, to suit different piping layouts. Another type is the tee, which enables the connection of three pipes, providing branching or combining options. The reducer is also important, as it helps in transitioning between pipes of different diameters.

There are also butt welded caps, which are used to seal the end of a pipe, and crosses, which facilitate the intersection of four pipes. Additionally, couplings are widely used for joining two pipes together.

The choice of butt welded fittings depends on various factors, including the type of fluid or gas being transported, the pressure and temperature requirements, and the specific application needs. These fittings are typically made from high-quality materials to ensure durability and resistance to corrosion.

In conclusion, understanding the different types of butt welded fittings available is essential for designing and maintaining efficient piping systems. With the right fittings, piping installations can operate smoothly and safely, meeting the demands of different industries and applications.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: