Alloy steel flanges are widely used in various industries due to their durability and versatility. These flanges are designed to connect pipes of different sizes and are crucial in maintaining the integrity and functionality of a piping system. This article will explore the durability and versatility of alloy steel flanges and discuss their advantages over other types of flanges.

Durability is one of the key characteristics of alloy steel flanges. These flanges are made from an alloy steel composition that includes elements such as chromium, nickel, and molybdenum, which enhance their strength and resistance to corrosion. The high strength of alloy steel flanges allows them to withstand high pressure and temperature conditions, making them suitable for applications in harsh environments.

Furthermore, alloy steel flanges have excellent corrosion resistance properties. The addition of chromium in the alloy composition forms a passive oxide layer on the surface of the flanges, protecting them from corrosion caused by moisture, chemicals, and other corrosive substances. This makes alloy steel flanges ideal for use in industries such as chemical processing, oil and gas, and offshore applications where they are exposed to harsh environments and corrosive materials.

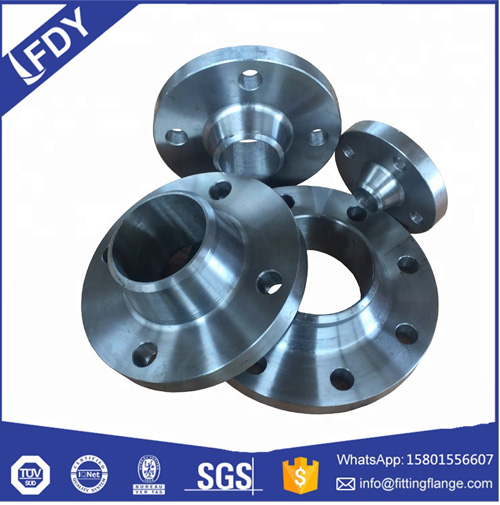

In addition to their durability, alloy steel flanges are also known for their versatility. These flanges are available in a variety of shapes, sizes, and classes to accommodate different piping requirements. They can be classified into several types such as slip-on flanges, weld-neck flanges, socket weld flanges, and blind flanges, among others, each with its own specific application.

Alloy steel flanges can also be customized to meet specific project requirements. They can be machined to match the dimensions and specifications of the connecting pipes, ensuring a seamless fit. This versatility allows alloy steel flanges to be used in a wide range of applications, including oil and gas pipelines, petrochemical plants, power generation facilities, and shipbuilding industries.

Another advantage of alloy steel flanges is their ease of installation and maintenance. These flanges are designed to be easily bolted or welded onto the pipes, reducing assembly time and labor costs. They also require minimal maintenance, thanks to their corrosion resistance properties. Periodic inspection and cleaning of the flanges are usually sufficient to ensure their long-term performance and reliability.

Furthermore, alloy steel flanges can be reused or recycled, contributing to their sustainability. When a piping system needs to be modified or replaced, the alloy steel flanges can be removed and reused in the new system. The ability to recycle these flanges minimizes waste and reduces the environmental impact of the industries that use them.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: