Flange is a part of shaft to shaft connection, which is used for the connection between pipe ends; it is also used for the connection between two equipment, such as reducer flange. In general, flange is used together with gasket and bolt. However, in the actual use process, the flange itself problems and improper use, will make the original tight leak free pipeline leakage, to enterprises and individuals bring serious economic losses and casualties. So, do you know one of the causes of flange leakage? What is the problem of flange itself?

In fact, one of the causes of flange leakage – flange itself problems, in addition to referring to poor quality flange, more refers to the flange sealing surface, but also because the actual situation is not applicable to this flange sealing surface.

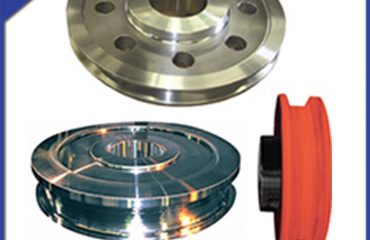

(1) As we all know, the commonly used flange sealing surface mainly includes plane, raised face (convex face in some standards), concave convex surface, tenon and groove surface and ring joint surface. The application scope of different flange sealing surface is different. For example, the contact surface of flat flange and matching sealing gasket is distributed on both sides of flange bolt center circle, which is mainly used for wide face flange and low-pressure pipeline In the system, concave convex flange is used together with non-metallic flat gasket, wrapped gasket, metal clad gasket, basic type or spiral wound gasket with inner ring, so as to reduce the possibility of gasket being impacted by pressure. It is easy to be aligned during assembly and can be used in occasions with strict sealing requirements.

2) The surface roughness of the flange sealing surface is one of the important factors affecting the sealing performance, so the flange sealing surface is generally machined. The surface roughness of flange sealing surface can be processed according to the actual requirements of customers, or the surface roughness of sealing surface can be selected according to relevant industry regulations, but it should be indicated in the order contract.

Moreover, the surface roughness of flange sealing surface is different with different gasket collocation. For example, when using non-metallic gasket, the surface roughness of flange processing is 6.3 μ m-12.5 μ m; when using polished metal gasket, higher flange machining accuracy is required, and the surface roughness is generally 0.4 μ m-1.6 μ M When metal flat gasket, metal tooth shaped gasket, metal corrugated gasket and metal clad gasket are used, the surface roughness of flange sealing surface needs ra3.2 ~ 1.6 μ m, which is difficult for the processing of large diameter flange surface. The unfavorable factors caused by large surface roughness can be compensated by using the method of surface coating flexible graphite plate or strip.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: