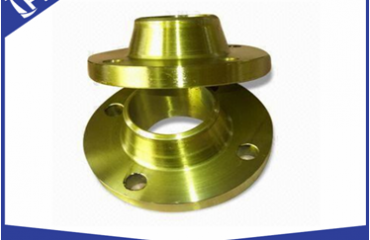

High-quality stainless steel flange must meet all aspects of accuracy requirements, only in this way can users be satisfied with the use, then what aspects of accuracy requirements should this product meet? First of all, the size specifications need to meet the accuracy requirements, because there are many specifications of this kind of product, different specifications will be used in different use environments, so it is necessary to meet the accuracy requirements in the specifications of the product, but in the industry, some manufacturers because there is no industry standard, so they are in the specifications. It is also inaccurate.

Moreover, the material of carbon steel flange also needs to meet the requirements of accuracy. As a pipeline connection product, there will be different material requirements under different transport media. If a manufacturer does not make the material for the use environment in production, or the material of the product in the aspects of strength, heat preservation, anti-corrosion and so on. The performance does not meet the requirements, but also is the decline in material accuracy, of course, the accuracy of materials and production costs will be related, so the more standard manufacturers, their product prices will also have a relative increase.

In addition, in the production of France, the forming process also needs better accuracy, which is directly related to the accuracy of its size. There are many manufacturers, although they have enough design accuracy in size, but due to the inadequacy of the forming process, eventually it will lead to disqualification in size, whatever it is. It is also necessary to meet the accuracy requirements under the production mode.

And because flange in the use process, not only must have enough heat resistance, but also to meet the requirements of sealing, which also requires products to meet its surface treatment and grinding accuracy requirements, there are also some products on the market in the use of just installed leakage, one of the biggest reasons is that The surface treatment did not meet the accuracy requirements. Of course, friendship is also related to the strength of the manufacturer. If the strength of the manufacturer is insufficient, or there is not enough equipment, or there is no good management in production, it will reduce the accuracy of this aspect.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: