Pipe fittings Use of value and range pipe fittings the welding of dissimilar metals can save precious metal and make the product function better. For example, the work of the tool parts (high-speed steel) and tail (medium carbon) of the butt welding, internal combustion engine exhaust valve head (heat-resisting steel) and the tail (structural steels) butt welding, aluminum and copper conductive joint butt welding.

Pipe fittings are used to weld the workpiece, such as steel strip, profile, wire, steel bar, rail, boiler pipe, oil and natural gas transmission pipeline.

Pipe fittings used in the components of the group welding will be easy to roll, forging, stamping or machining parts to weld into a mixed part to decrease the cost. For example, the car direction axle shell and rear axle housing butt welding, various connecting rods, rod butt welding, as well as specific parts of the butt welding. The pipe fittings are used in the butt welding of the annular workpiece such as automobile rims and bicycles, the butt welding of the motorcycle wheels, the butt welding of various chain rings, etc.

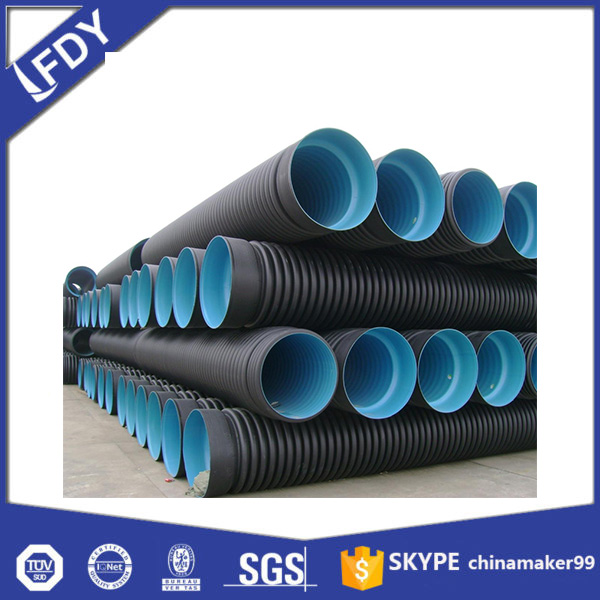

With the development of petrochemical industry, construction projects tend to be more complex and large, pipe fittings according to the situation of the different and different, a variety of pipes for the branch, bending, diameter of the pipe link accessories, the use of the environment than straight pipe, the thickness of the pipe, material depends on the use of fluid medium, pressure, temperature and so on.

The elbow is used to bend the pipe, usually to change the direction of the pipe. According to the bending radian 90 degrees, 45 degrees, 30 degrees, etc., according to the bending radius of 1D, 1.5D, according to the material of carbon steel elbow, stainless steel elbow, alloy elbow, etc., according to the manufacturing process of the stamping elbow, forging elbow, etc. in the piping system layout, it is generally advisable to choose R=1.5D elbow Connection, r=1d elbow is usually used in a more compact piping system or to reduce costs.

When using 1D elbow, the maximum working pressure should not exceed 0 of the same specification 1D elbow. 8 times times. Miter elbows are usually used for low-voltage (design pressure s2. 0MPA), the low temperature, the fluid medium easement large size pipeline. When the single pitch angle of oblique elbow is greater than 45 degrees, it is not suitable for poisonous, combustible medium, withstanding vibration, pressure pulsation and the pipeline with alternating load due to temperature change.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: