High-pressure flange is widely used, but its quality requirements are very high, the traditional high-pressure flange is the use of gasket (elliptical pad, octagonal pad, lens pad, etc.) of plastic deformation to achieve the sealing effect, connected to the pipe end, so that the pipe and pipe connected to the parts, flanges have holes, double head bolts make two flange tight.

High-pressure flange in the use of, has a good role and value, the prerequisite is to be in accordance with the appropriate method to use, in the installation of the first to follow the guidance of experts reasonable installation, to better ensure the use value, and better prolong the service life. Secondly, during the installation, the gasket may not be replaced with the ordinary gasket, must choose the appropriate gasket to ensure the best sealing effect.

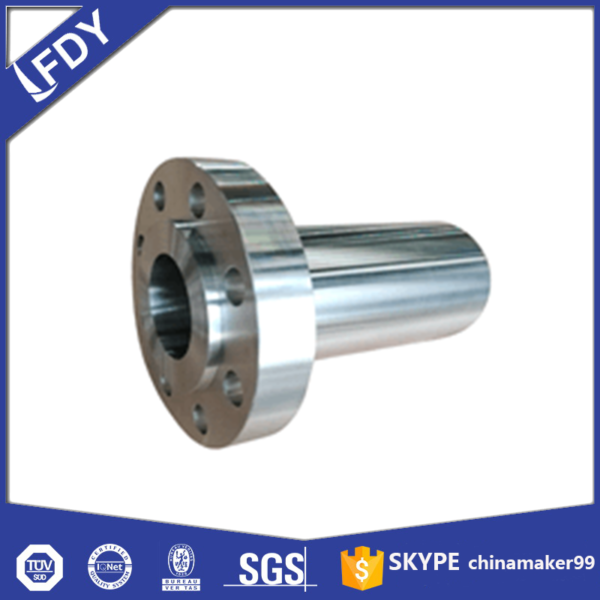

Characteristics of high pressure flange

1.Sealing principle belongs to plastic deformation

2.Bolt Connection

3, the bolt must bear the tensile force, the temperature difference stress, and bears the bending moment, the torque and so on many external stress

4, bulky, heavy weight, installation positioning is very difficult.

5, the sealing performance is not stable, especially in the harsh (high temperature, high pressure, the medium is highly toxic) in the case of easy to produce leakage, resulting in serious consequences.

Now let’s introduce the application features of alloy steel flanges.

Alloy flanges are two large-caliber pipe connections, usually two flange pieces plus a number of fastening bolts, alloy flanges are made of steel flanges. Alloy flanges are used in piping and pipelines of special characteristics, and are used for high temperature and high pressure positions. Its common material has 12cr1mov, 15CrMo, P91, P22, 10crmo910 and so on.

The liquid shrinkage and solidification shrinkage of alloy in the production of alloy flange are reduced by volume shrinkage, which is the basic cause of shrinkage and shrinkage defects in castings. The solid-state shrinkage of the alloy is also a volume change, but it only causes the change of the outer dimension of the castings, so it is usually expressed by the line shrinkage rate. Solid-State shrinkage is the source of defects such as internal stress, deformation and crack in castings. Low-carbon steel flange has good plasticity strength, it becomes hard after adding proper amount of charcoal, and the ductility decreases. Alloy flange connection may need to withstand very high tensile, compressive, torsional, shear strength, large flanges is a good choice.

The main drawback of alloy flanges is that it does not guarantee leakage. This is the lack of design: The connection is dynamic, and such as thermal expansion and fluctuating cycle load will cause the flange between the movement, affecting the function of flanges, so that the integrity of the flange damage, resulting in leakage. Any product can not be without defects, just try to control the product’s deficiencies to the minimum, so the company in the production of alloy flange as far as possible to improve the performance of the product, so that it plays the greatest role.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: