The selection of flange material shall be determined according to the nature of the flange bearing load, stress state, stress size, working temperature, environmental medium, service life, requirements for conductive magnetic conduction, process function, material source and price.

Stainless steel Flange According to the mechanical properties, stainless steel flanges can be divided into tensile flange, compression flange, torsion flange and bending flange, according to the shape can be divided into disc-shaped flange, annular flange, flange piece, spiral flange, truncated cone scroll flange and torsion bar flange and so on. Oil quenching and tempering slip on flange is in the slip on flange lathe processing to the size after the modulation to strengthen treatment, basically no residual stress exists, forming flange after the low-temperature tempering, size change is very small, heat resistance is better than cold drawing enhanced slip on flange. Ordinary cylindrical flange because of the simple manufacture, and according to the conditions of the load can be made of various types, simple structure, so the most widely used.

Carbon Framping Welding Flange and the piano flat weld flange After the cold drawing to produce the larger residual stress, after processing the flange, has the big residual stress, after tempering the size change is big, difficult to control the dimensional accuracy. In determining the profile and size of the material cross-section, priority should be given to the series sizes delineated by the national scale and the ministerial scale, so as to avoid the selection of materials of non-standard series specifications. For the flange with lower load precision and less stress, hot rolled steel can be selected.

Large and medium-sized flange, for the load accuracy and high stress deputies with cold drawn material or cold drawn after finishing steel. Common flange wire diameter of 20 mm under the cold roll method, stainless steel flange in the manufacture of pressure or polishing treatment, can improve the bearing capacity and surface finish.

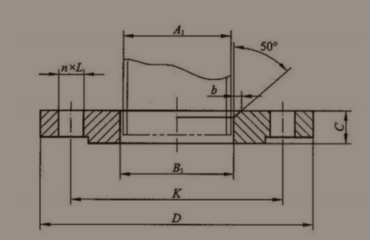

Disc-shaped flange is in the shaft is tapered and bear the load of the special flange, under the load deformation, saving a certain potential energy, when the bolts are slack, disc flange release the Department of potential energy to maintain the flange connection between the pressure to meet the sealing requirements.

Medium and small flange, in particular, the spiral tensile flange, should be preferred by the enhanced treatment of the slip on flange, isothermal cold drawing welding flange and oil quenching temper slip on flange, with high strength and good surface quality, fatigue function than ordinary quenching temper welding flange, simple processing, good workmanship, quality is not disorderly. The stress distribution of disc flange decreases from inside to outside, which can realize the effect of low stroke and high compensation force. Generally speaking, the flange should have high bearing pressure limit, exhaustion limit, impact toughness and good heat and corrosion resistance function, etc., commonly used materials have reference.

we have our own pipe fitting factory since 1998 ,which covers 100 acres. In 1998, we invested and set up a new flange factory. Up to now, we have a complete production system, and become a professional and competitive group in this field.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: