The main design disadvantage of dual phase steel flange is no leakage. This is a deficiency in that design. The connection is dynamic, stainless steel flange, and periodic loads such as thermal expansion fluctuation will cause the movement between flange faces, affect the function of flange, damage the integrity of flange and lead to leakage. Then, let’s learn about the main design shortcomings of dual phase steel flange!

Due to these advantages of dual phase steel flange, sewage treatment pipeline, deep-sea operation, seawater desalination, various acid-base environment and good wear and corrosion performance, it can be used for 4 ~ 5 years more than ordinary stainless steel. For example, the service life of dual phase steel flange for pipeline in seawater will be shortened, and the labor cost is relatively high.

1 . The yield strength is more than one time higher than that of ordinary austenitic stainless steel, and has sufficient plastic toughness required for forming.

2 . It has excellent stress corrosion cracking ability, especially in chloride ion environment.

3 . Dual phase steel is highly corrosive. It can replace high alloy austenitic stainless steel or even etch alloy in some media such as acetic acid and formic acid.

4 . It has good local corrosion properties. Compared with austenitic stainless steel with the same alloy content, the wear corrosion and fatigue corrosion properties are better than austenitic stainless steel

The larger bolts of dual phase steel flange must be consistent with the larger nuts. Dual phase steel flange special steel flange means that larger diameter bolts need to create conditions for fastening nuts. Unexpectedly, the larger the diameter of the bolt, the more curved the flange applied. The method is to increase the wall thickness of the flange part. The whole device of American standard flange needs very large size and weight, which becomes a special problem in offshore environment. Because in this case, weight is always the main issue that must be paid attention to.

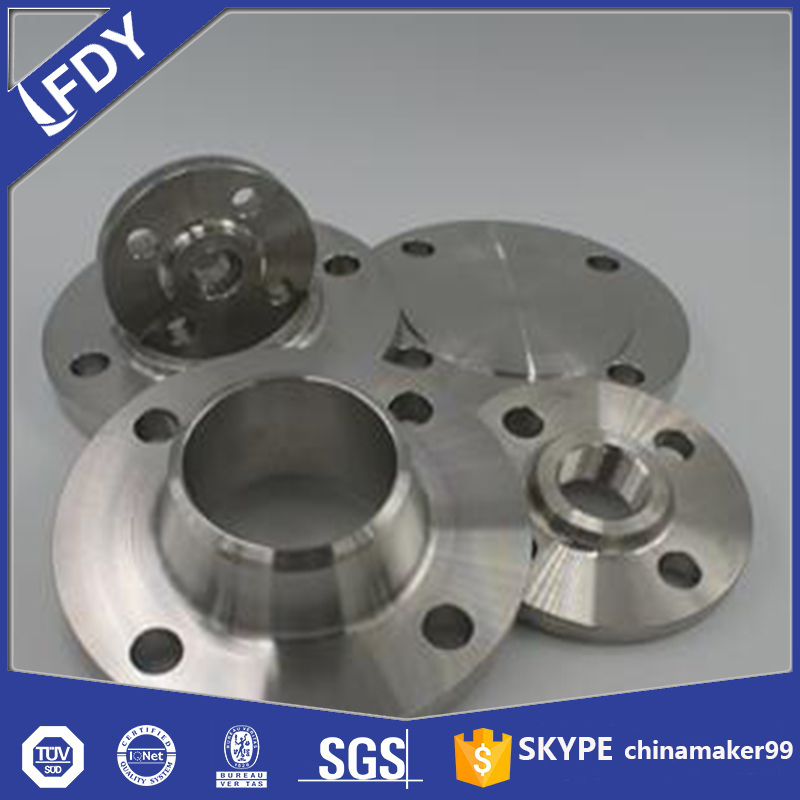

Dual phase steel flange is a movable flange, which is generally installed on water supply and drainage accessories. Expansion joints are common. When the manufacturer leaves the factory, there is a flange at both ends of the expansion joint, which is directly connected with the pipeline and equipment under construction through bolts.

Stainless steel and oxidant have passivation effect, forming a tough and dense chromium rich oxide protective film Cr2O3 on the surface, which can effectively prevent the further occurrence of oxidation reaction. Other metal pipe materials, such as galvanized pipe and Japanese standard flange copper pipe, have low passivation ability. This is an important reason why the corrosion resistance of galvanized pipe and copper pipe is far inferior to that of stainless steel pipe.

The two sealing surfaces of the flange bolt squeeze the flange gasket to form a seal, but this will also lead to the destruction of the seal. In order to maintain the seal, the neck flange must maintain a large bolt force. To do this, the bolts must be further enlarged.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: