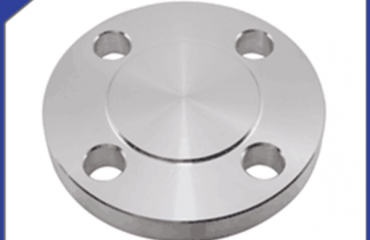

Polishing method of dual phase steel flange

1. There are four polishing methods of dual phase steel flange: manual, mechanical, chemical and electrochemical. Polishing can improve the corrosion resistance and decoration of the flange. The existing electrolytic polishing solution for stainless steel still uses phosphoric acid and chromic anhydride. During polishing and cleaning, some chromium and phosphorus will be discharged into the wastewater. Environmental pollution.

2. Passive film will be formed on the surface of dual phase steel flange, and the oxide film will begin to dissolve at the same time. Due to the micro inconsistency of the surface of dual phase steel flange, the micro convex part of the surface will be dissolved first, and the dissolution rate will be greater than that of the concave part. The film dissolves and forms almost simultaneously, but at different speeds. As a result, the surface roughness of the dual phase steel flange becomes lower and a smooth and shiny surface is obtained.

3. Polishing can make up for some surface defects such as surface pores and scratches, so as to improve the fatigue resistance.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: