The shape and size of the casting blank are accurate, the machining amount is small and the cost is low, but there are casting defects (porosity, crack and inclusion); the internal structure streamline of the casting is poor (if it is a cutting part, the streamline is worse);

The advantages of the casting are that it can make a more complex shape and the cost is relatively low;

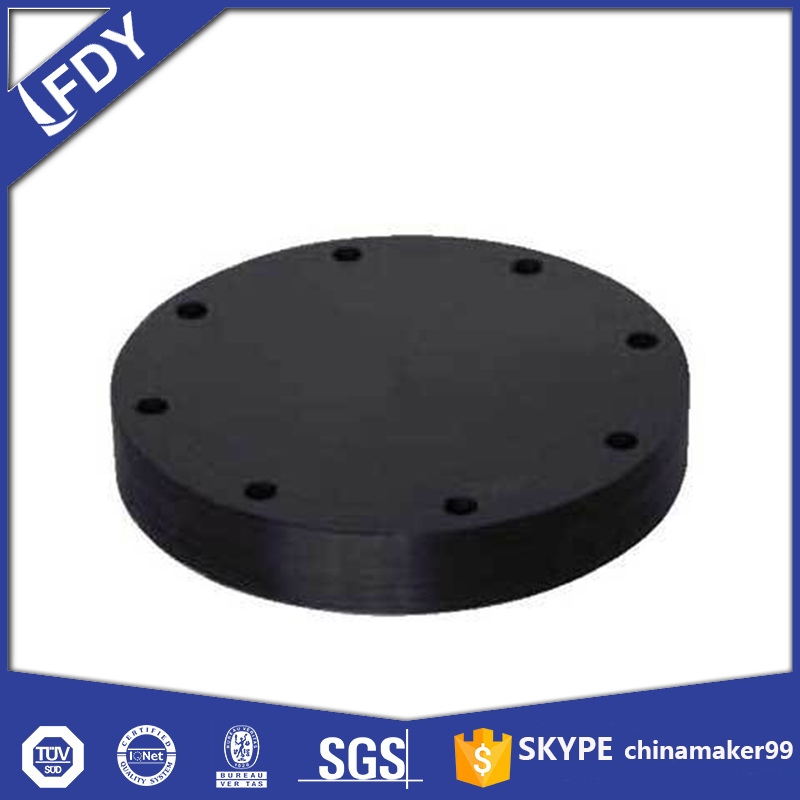

The difference between casting flange and forging flange can be distinguished from production process, for example, centrifugal flange belongs to Blind flange.

A cast flange.

Centrifugal flange is a kind of flange produced by precision casting. Compared with ordinary sand casting, the structure of centrifugal flange is much finer and its quality is improved. It is not easy to have loose structure, porosity, sand hole and other problems.

First of all, we need to know how the centrifugal flange is produced. The process and products of centrifugal casting to make flat welding flange are characterized by the following process steps:

① put the selected raw material steel into medium frequency electric furnace for smelting, so that the temperature of molten steel can reach 1600-1700 ℃;

② preheat the metal mould to 800-900 ℃ and keep constant temperature;

③ start the centrifuge, inject the steel water in step ① into the metal mold after preheating in step ②;

④ the casting is naturally cooled to 800-900 ℃ and kept for 1-10 minutes;

⑤ cool with water to near normal temperature, demould and take out the casting.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: