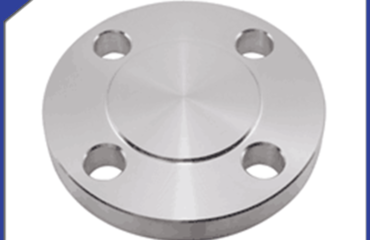

Production process flow of forged flanges:

The forging process generally consists of the following processes: selecting high-quality steel billets for cutting, heating, forming, and cooling after forging. The forging process methods include free forging, die forging, and membrane forging. During production, different forging methods are selected based on the size of forging quality and the number of production batches.

Free forging has low productivity and large machining allowance, but the tools are simple and versatile, making it widely used for forging single piece and small batch forgings with relatively simple shapes. Free forging equipment includes air hammers, steam air hammers, and hydraulic presses, which are suitable for the production of small, medium, and large forgings, respectively. Die forging has high productivity, simple operation, and is easy to achieve mechanization and automation. Die forgings have high dimensional accuracy, small machining allowance, and more reasonable fiber structure distribution, which can further improve the service life of the parts.

Basic process of free forging: During free forging, the shape of the forging is gradually formed by forging the blank through some basic deformation processes. The basic processes of free forging include upsetting, elongation, punching, bending, and cutting.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: