Production processes are mainly divided into forging, casting, cutting and rolling.

The cast flange has accurate blank shape and size, small processing capacity and low cost, but there are casting defects (pores, cracks and inclusions); The internal organization streamline of the casting is poor (if it is a cutting part, the streamline is even worse);

Forged flanges generally contain less carbon than cast flanges and are not easy to rust. Forged flanges have good streamline, dense structure and better mechanical properties than cast flanges;

Improper forging process will also lead to large or uneven grains and hardening cracks, and the forging cost is higher than that of cast flange.

Forgings can withstand higher shear and tensile forces than castings.

The advantage of casting is that it can produce a more complex shape and low cost;

The forging has the advantages of uniform internal structure and no harmful defects such as pores and inclusions in the casting;

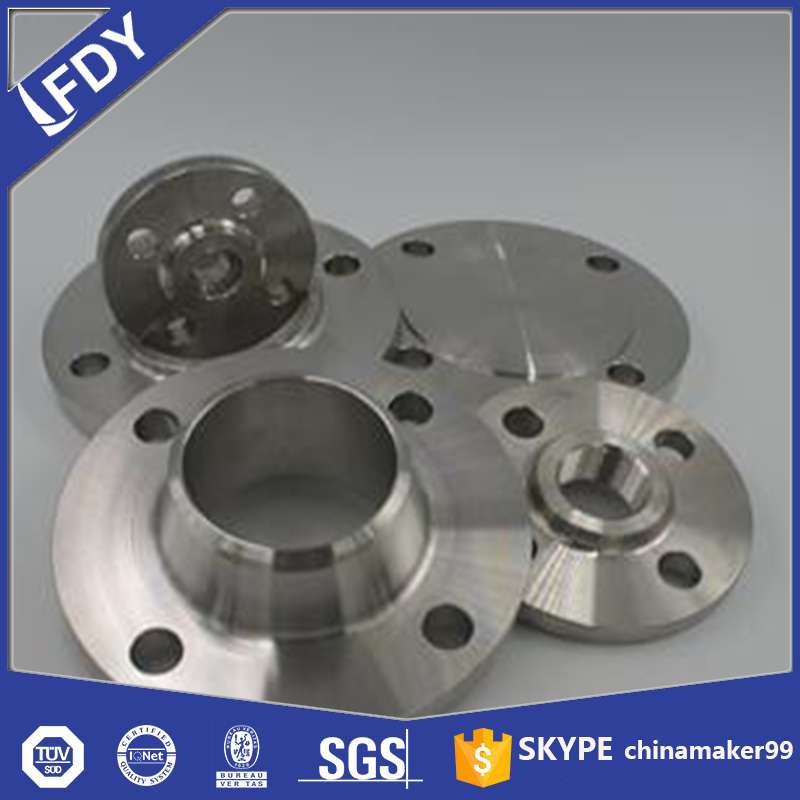

The difference between cast flange and forged flange is distinguished from the production process. For example, centrifugal flange belongs to a kind of cast flange.

Centrifugal flange is produced by precision casting method. Compared with ordinary sand casting, this kind of casting has much finer structure and improved quality. It is not easy to have problems such as loose structure, pores, trachoma and so on.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: