Introduction: The industrial infrastructure plays a crucial role in ensuring the smooth operation of various sectors such as manufacturing, construction, and oil and gas exploration. Central to this infrastructure are alloy steel flanges, essential components that connect pipes and equipment together while withstanding high pressures and temperatures. As the demand for robust and reliable infrastructure continues to grow, alloy steel flanges are poised to shape the future of industrial infrastructure due to their superior properties and versatility.

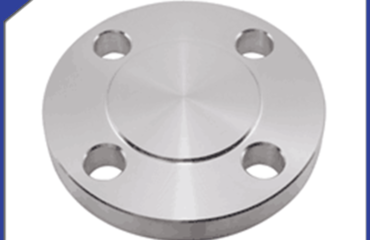

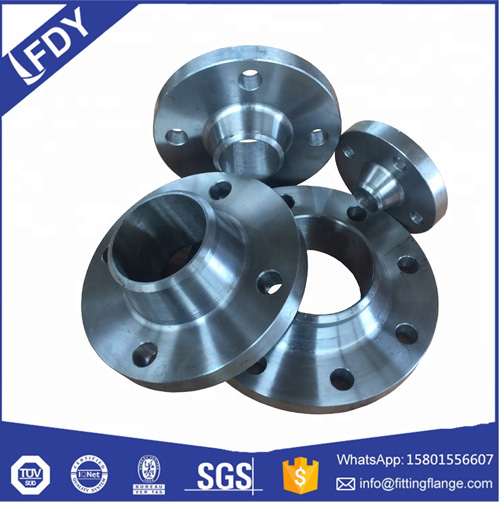

Superior Properties: Alloy steel flanges are a preferred choice over conventional carbon steel flanges due to their superior mechanical properties. Alloy steel, composed of various elements such as chromium, molybdenum, and nickel, exhibits excellent corrosion resistance, high tensile strength, and exceptional heat resistance. These properties enable alloy steel flanges to withstand extreme environments and conditions, making them ideal for industries that require durable and long-lasting infrastructure solutions.

Versatility: One of the key advantages of alloy steel flanges is their versatility in various applications. They can be used in a wide range of industrial sectors, including oil and gas, chemical processing, petrochemical, power generation, and water treatment plants. Alloy steel flanges are especially well-suited for applications that involve high-pressure systems or corrosive environments, where their exceptional properties provide a reliable and safe solution.

Rising Demand and Challenges: With rapid industrialization and urbanization, the demand for industrial infrastructure is increasing. This surge in demand poses several challenges that alloy steel flanges are well-equipped to address. Firstly, the need for infrastructure that can withstand higher pressures and temperatures necessitates the use of alloy steel flanges. Additionally, the growth of offshore oil and gas exploration requires flanges that can resist corrosion caused by seawater and harsh weather conditions. Alloy steel flanges can meet these challenges, providing a reliable and efficient solution for the future of industrial infrastructure.

Technological Advancements: Technological advancements in engineering and manufacturing processes have further enhanced the capabilities of alloy steel flanges. Precision machining techniques, such as CNC machining, enable the production of complex flange designs with high precision and accuracy. This ensures a perfect fit and tight seal, minimizing the risk of leaks or failures. Additionally, advancements in metallurgical techniques allow for the development of alloy steel flanges with improved properties, such as higher corrosion resistance and greater fatigue strength.

As the demand for robust industrial infrastructure continues to rise, alloy steel flanges are positioned at the forefront of shaping the future of this sector. The superior properties of alloy steel, including its corrosion resistance, high tensile strength, and exceptional heat resistance, make alloy steel flanges ideal for applications in various industries. Their versatility and ability to withstand extreme conditions make them an indispensable component in the construction of pipelines, equipment, and structures. With ongoing technological advancements, alloy steel flanges will continue to play a vital role in ensuring the reliability and longevity of industrial infrastructure for years to come.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: