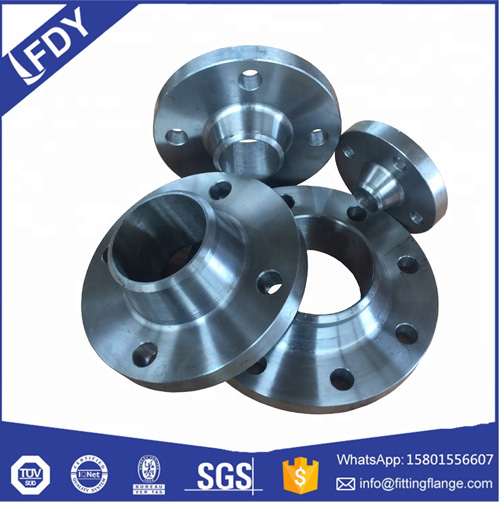

Alloy steel flanges are two large-caliber pipe connections, usually two flange pieces plus a number of fastening bolts, alloy flange is made of stainless steel flanged. Alloy flange for special characteristics of pipelines and pipelines, used for high temperature and high pressure position, its common materials are 12cr1mov, 15CrMo, P91, P22, 10crmo910 and so on. Low-carbon steel flange has good plasticity strength, it becomes hard after adding proper amount of charcoal, and the ductility decreases.

Alloy steel flange connection may need to withstand very high tensile, compressive, torsional, shear strength, large flange is a good choice, alloy flanges The main design disadvantage is that it can not guarantee no leakage. The connection is dynamic, and the periodic load, such as thermal expansion and fluctuation, will cause the flange to move, affecting the function of the flanges, thus causing the integrity of the flange to be compromised, resulting in a leak.

The liquid shrinkage and solidification shrinkage of alloy in the production of alloy steel flange are reduced by volume shrinkage, which is the basic cause of shrinkage and shrinkage defects in castings. Although the solid-state shrinkage of the alloy is also a volume change, it only causes the change of the external dimension of the castings, so it is usually indicated by the line shrinkage rate that the solid shrinkage is the source of the defects such as the internal stress, deformation and crack of the castings.

Alloy steel flanges used in the alloy steel stud should be the use of high-grade high-quality products, nut materials are often based on the bolts with the material to determine, these combinations in the general standards are provided. In general, the nut material should be slightly lower than the bolt material, and ensure that the nut hardness than the bolt hardness of HB30 around. According to the different structure types, bolts can be divided into six-angle head bolts and two-head bolts (also known as stud), while the two-head bolts are divided into wire and non-tong wire. The hexagonal head bolts used on alloy flanges are often combined with flat-weld flanges and Non-metallic gaskets to operate in a more moderate condition, the commonly used materials of hexagonal head bolts are BL3 or q235b, and the double head bolts are often used with weld neck flanges under harsh operating conditions. There is no change of cross section shape on the wire type double head bolt, so its carrying capacity is strong, but the relative bearing capacity of the non-tong wire type bolts used on the alloy flange is weaker.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: