Now the common standard of carbon steel flange is generally divided into: sy/t5037-2000 (Ministry of Standard, also known as ordinary fluid pipeline with spiral seam submerged arc welded steel pipe), gb/t9711.1-1997 (GB, also known as the oil and gas industry transportation pipe Delivery Technical conditions Part I: A-class steel pipe (to the current requirements of strict gb/t9711.2B steel pipe), API-5L (American Petroleum Association, also known as pipeline steel pipe; PSL1 and PSL2 two levels ), sy/t5040-92 (spiral seam submerged arc welded pipe for pile).

The production process of carbon steel flange is simple, the production efficiency is high, the cost is low and the development is fast. The strength of spiral welded pipe is generally higher than that of straight seam welded pipe, which can produce pipe with larger diameter with narrower billet, and can produce pipe with different diameters with same width. Liaocheng Jia Bin Steel Pipe Co., Ltd. supply Spiral Pipe. But compared with the same length of straight seam tube, the weld length increases $number and the production speed is lower. Therefore, the smaller-caliber welded pipe mostly adopts straight seam welding, and the large diameter welded pipe is mostly spiral welded.

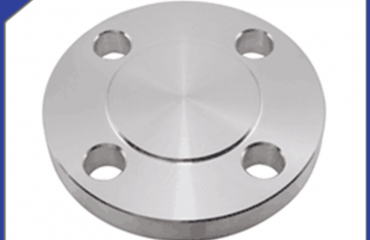

The common material is cast carbon steel grade WCB, forgings A105, or q235b, A3, #, # steel, 16 manganese, 45th Steel, $literal and so on.

Usually to prevent rust flange surface plating layer (yellow zinc, white zinc, etc.), or brush anti-rust oil and spraying anti-rust paint treatment.

The inspection process is as follows:

Raw material Inspection–leveling inspection–butt welding inspection–inspection- test—

In order to ensure product quality, we have developed a sound quality plan, on-site work procedures and testing, test plans.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: