Due to the initial standardization work of stainless steel butt welding flanges, there have been few varieties and specifications of stainless steel butt welding flanges, small production scale, and poor flowability for a long time. There are many mid to low end products, but few mid to high end products. Some high-end enterprises produce high-end products. For Chinese stainless steel welding flange enterprises, there is a phenomenon of lack of concentration, too many factories, dispersion, and product quality not keeping up. For the fastener mold market, disorderly competition is the dispersion of the market. Now, let’s explain the functions and precautions of stainless steel butt welding flanges.

1. Main functions of stainless steel butt welding flanges

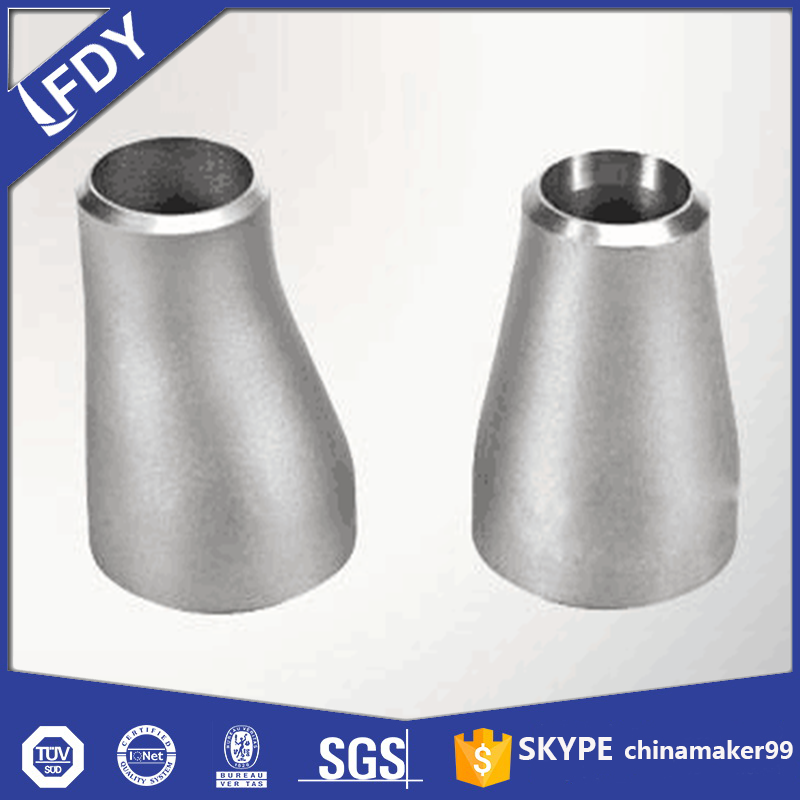

Stainless steel butt welded flanges are disk shaped parts that are most common in pipeline engineering. In pipeline engineering, stainless steel flanges are mainly used for pipeline connections. Here, the main role of stainless steel butt welding flange manufacturers is to:

1. Connect the pipeline and maintain its sealing performance;

2. Stainless steel butt welding flange, convenient for replacing a certain section of pipeline;

3. Is the stainless steel butt welding flange easy to open and check the condition of the pipeline?

4. Conveniently close some pipelines.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: