Welding flange is not easy to deform, good sealing, wide application, have the corresponding rigidity and elasticity requirements and reasonable welding thinning transition, the welded seam is joint distance, joint from welding temperature deformation, it adopts a more complex structure of the mouthwash, suitable for pressure or temperature fluctuations in the pipeline or high temperature, high pressure and low temperature pipe, generally used for more than 2.5 of the pipeline and valve connections; also used to transport expensive, flammable, explosive media on the road. And in the non-ferrous stock of copper stock behind the market more, later, the international commodity prices in the background of high innovation to win the probability of carbon steel flange stock market is increasing. In order to prevent carbon steel pipe pieces because of heating and produce eye erosion, welding current should not be too large, less than 20% of carbon steel electrode, arc should not be too long, between the layers of fast cold, narrow welding.

Large flange general caliber is above 2000, it is a kind of flange product exceeding the standard flange stipulation application scope, its production and the acceptance and so on request are not subject to the sample flange standard restriction, but by the construction side provides. Therefore, spraying (throwing) derusting is an ideal rust-removing method for pipeline anticorrosion. Flange manufacturers in the production and welding of strict control of technical parameters, to ensure that the production and use of full play the role and value.

Because of the high stress in the elbow of stainless steel elbow.

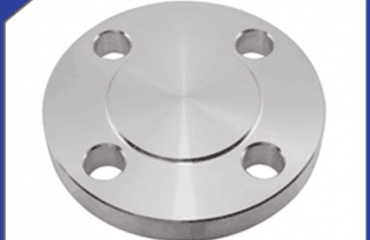

Connected to the tube end. The finished product with better quality is obtained by using the simulated optimization process parameters, and the results can guide the rolling production of stainless steel tee. According to the connecting parts can be divided into container flanges and pipe Flanges, according to the structure of the type, the whole flange, looper flange and threaded flange. For example, there are a long-distance pipelines, it is necessary to put a pipe into the entire pipeline, in this pipeline also installed on the valve, sight, telescopic and so on, which can be welded with welding, but after the repair and maintenance will not be removed? So the majority of such pipelines will be selected flange manufacturers of slip on flange plate joints, to facilitate later maintenance and replacement.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: