The types of steel butt welded pipe components listed in the product standard include elbows, tees, crosses, reducers (also known as reducers), pipe caps, bends, flanged short joints, branch pipe seats, etc.

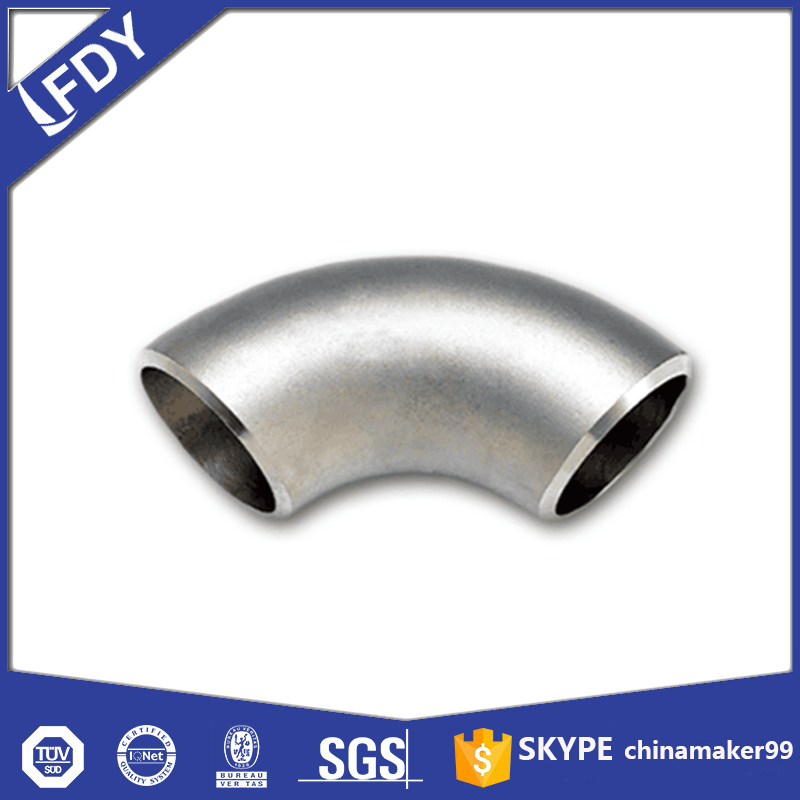

The commonly used elbows are divided into 45 ° elbows, 90 ° elbows, and 180 ° elbows according to their bending angles; According to the bending radius, it is divided into long radius elbows (R ≈ 1.5DN, which means the bending radius is about 1.5 times the nominal diameter) and short radius elbows (R ≈ 1.0DN, which means the bending radius is about 1 time the nominal diameter); Among them, there is also a reducing elbow in the 90 ° long radius elbow. In addition, according to the needs of the piping direction, there will also be special angle elbows, such as 60 °, 88 ° 25 ″ elbows, etc.

Tees and crosses can be divided into equal and reduced diameters, and the nozzle ends of equal diameter tees and crosses are of the same size; The main pipe connection size of the reducing tee and cross is the same, while the connection size of the branch pipe is smaller than the connection size of the main pipe.

There are two types of reducers: concentric and eccentric. The large end diameter and small end diameter of concentric reducers are on the same axis; The large end diameter and small end diameter of the eccentric reducer are parallel axes, with one side of the small end diameter parallel to the outer edge of the large end diameter.

Bends are ordered according to the bending angle and bending radius. Generally, straight pipe sections are required at both ends of the bend, and the bending radius is usually 2.5 to 3 times the outer diameter of the pipe (R ≥ 2.5D to 3D).

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: