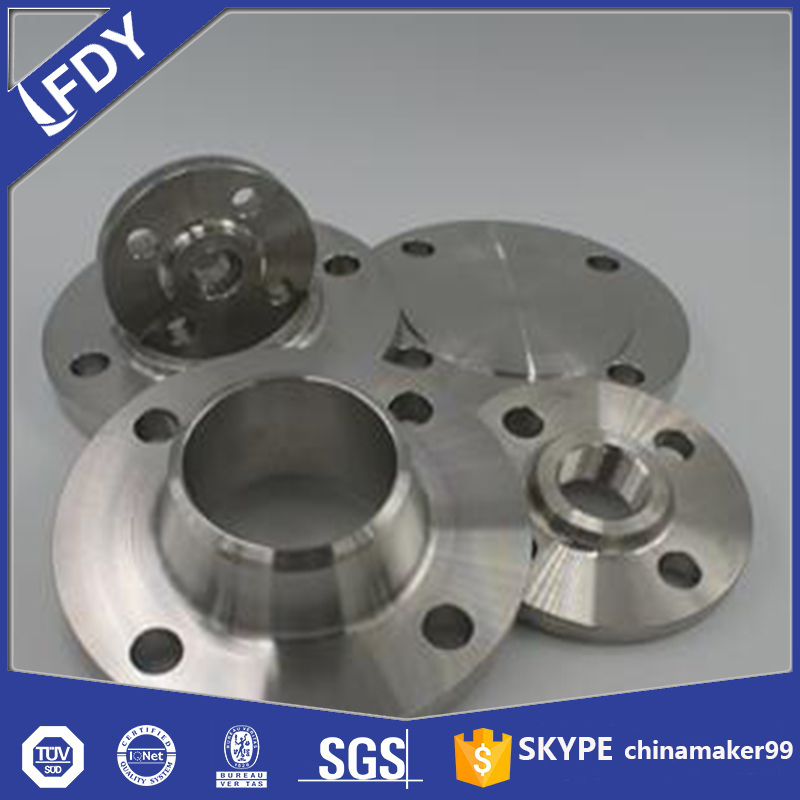

Forged flanges are made by shaping heated metal using compressive forces, resulting in a product with high strength and durability. This makes them ideal for applications that require resistance to extreme temperatures, pressures, and stresses.Forged flanges are manufactured to strict tolerances, ensuring a tight seal between pipes or fittings. This helps to prevent leaks, reducing the risk of accidents or damage to equipment.

Forged flanges are often made from materials such as stainless steel, which provide excellent corrosion resistance. This makes them suitable for use in harsh environments where exposure to corrosive substances is common.

Forged Flanges come in a wide range of sizes, shapes, and materials, making them highly versatile and suitable for a variety of applications. They can be customized to meet specific requirements, ensuring a precise fit and optimal performance.Forged flanges are able to withstand high pressures and temperatures, making them suitable for applications in industries such as oil and gas, chemical processing, and power generation. Their strength and durability make them a reliable choice for demanding environments.

The benefits of using forged flanges in industrial applications make them a popular choice among engineers and manufacturers. Their strength, durability, leak resistance, corrosion resistance, versatility, cost-effectiveness, safety, high pressure and temperature resistance, and ease of installation and maintenance make them a reliable and efficient component in a wide range of industries.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: