The existence of dual phase steel flange restricts the growth of grains between dual phases. Dual phase stainless steel maintains fine grains, and the total area of grain boundary of dual phase stainless steel is larger than that of single-phase steel. Therefore, dual phase stainless steel has high strength, especially yield strength, ensuring certain plasticity and toughness. Another characteristic of mechanical properties of duplex stainless steel is related to the change of duplex ratio. Generally speaking, the strength, especially the yield strength, increases with the increase of ferrite content; With the increase of austenite content, plasticity and toughness increase.

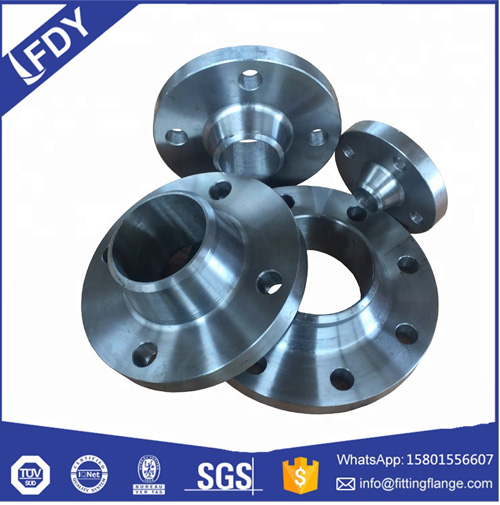

Dual phase steel flange is a flange produced with dual phase steel bars, ingots and plates as raw materials. Dual phase steel flange refers to the removed flange manufactured with dual phase steel bars as raw materials. It is also a new flange. Dual phase steel flange is a kind of flange, which is used for the connection between pipe ends.

Dual phase steel flange has excellent corrosion resistance, especially the ability of point corrosion resistance, gap corrosion resistance and stress corrosion resistance in medium is better than other kinds of stainless steel. The corrosion resistance of duplex stainless steel is related to its chemical composition and duplex structure. All alloy elements in duplex stainless steel have good corrosion resistance. Chromium is the basic element to improve the corrosion resistance of steel. It forms a stable passive film and has strong self repair ability to the damaged passive film. The content of chromium in duplex stainless steel is far more than 13%.

Molybdenum can improve the stability of the passivation film, and argon can promote the uniformity of the passivation film. In terms of the ability to improve the pitting index, the dual phase structure of duplex stainless steel with 20 ~ 30 times chromium is also conducive to the improvement of corrosion resistance. At the initial stage of the development of duplex stainless steel, due to the different composition and potential of the two phases in the steel, people are worried that electric corrosion will occur. However, the research and practice results show that as long as the two phases in the duplex stainless steel flange are in the passivation zone and both phases reach the passivation state, the steel two-phase structure makes the steel grain finer and the grain boundary area larger, resulting in the reduction of the concentration of corrosion precipitates at the grain boundary. In addition, Once the precipitate produces the disc chromium zone, it will immediately lose favor from the ferrite phase with high chromium and restore the concentration of chromium.

The two flanges have a hole, and the two flanges can be closely connected by bolts. In fact, duplex steel flanges are not necessarily fixed with stainless steel bolts. Stainless steel bolts are only used to facilitate disassembly. Because bolts made of carbon steel are easy to rust. It can also be selected in case of no fire or other special circumstances.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: