Anchor flange is a kind of engineering component. In places with low pressure, short pipes with thrust rings can be used instead, or called through wall sleeves. For the connection of fixed pipes that are required to be buried underground or not maintained for life, and when the pressure is required to be high, conventional flanges can not ensure the safe and reliable operation of high-pressure pipes. The utility model relates to an axisymmetric ring body with a flange, both sides of the flange are symmetrical flange necks, and the ports of the two flange necks are respectively welded with the ports of the pipeline and embedded in the anchor pile. Because the two flanges connected by bolts in the prior art are combined together, the sealing gasket is cancelled to form an integral flange, which is connected with the pipeline by welding and fixed with the anchor pile by its flange and flange body, so it can be used to fix the connection of the pipeline.

Size — 1/2″ -80″

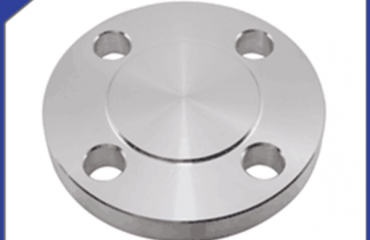

Type — carbon steel weld neck flange ,long weld neck flange , slip on flange ,socket weld flange, threaded flange,blind flange,orifice flange ,lap joint flange ,plate flange ,etc.

Face–RF, FF, MF, MFM, RJ, TG, RTJ, SRF

Thickness–Class 150Lbs, 300Lbs, 600Lbs, 900Lbs, 1500Lbs, 2500Lbs, /PN6,PN10,PN16,PN20,PN25,PN40/ Class A, B, C, D, E

Standard –ASME B16.5, ASME B16.47, ASME B16.36,DIN 86341-2000, DIN2505,etc

Material —

Carbon Steel–ASTM A105, Q235,

Low temperature carbon steel–A350LF2,A350LF3,

Pipeline Steel –ASTM A694 F42,F46,F52,F56,F60,F65,F70,F80

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: