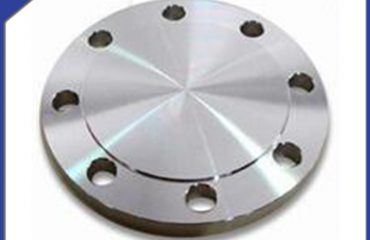

FIGURE 8 BLIND FLANGE is a solid plate or common steel plate used to block the pipeline equipment at the connection of two flanges. The purpose is to test the pressure, leak and block the pipeline of pipeline equipment.

The product pipe size range is & frac12; “to 96”, and the flange grade range is 150 × 104m3. Blind flange products use convex or ring tongue and tenon joint gasket surface. Blind flange products have two series a (MSS sp44) or B (API 605), which conform to ASME / ANSI B16.5 and b16.47.

The production process is mainly divided into forging, casting, cutting and rolling.The inner and outer diameter and thickness of the flange are directly cut out on the middle plate, and then the bolt hole and water line are processed. The flange produced in this way is called cut flange. The maximum diameter of such flange is limited to the width of the middle plate.

The process of using the middle plate to cut the sliver and then roll it into a circle is called rolling, which is mostly used in the production of some large flanges. After coiling, welding, flattening and processing of waterline and bolt hole are carried out.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812  Email:

Email:  Whatsapp:

Whatsapp: