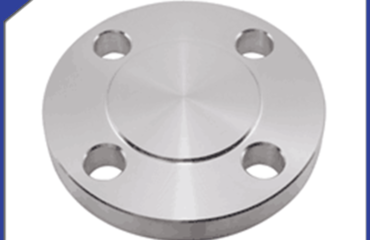

Stainless steel flange is also called flange or flange. The flange is the part that makes the pipe and the pipe connect with each other, and is connected to the pipe end. There are holes in the flange, and the bolts make the two flanges tightly connected. The stainless steel flange connection is easy to use and can bear large pressure. Flange connection is widely used in industrial pipeline.

1、 The welding rod shall be kept dry when used. The titanium calcium type shall be dried at 150 ℃ for 1 hour, and the low-a hydrogen type shall be dried at 200-250 ℃ for 1 hour to prevent the coating of the welding rod from sticking oil and other dirt, so as to avoid the increase of carbon content in the weld and the impact on the quality of the weldment.

2、 When stainless steel flange pipe is welded, carbide is precipitated by repeated heating, which reduces corrosion resistance and mechanical properties.

3、 In order to improve the corrosion resistance and weldability of stainless steel flange, proper amount of stable elements Ti, Nb, Mo, etc. are added. The weldability of stainless steel flange is better than that of chromium stainless steel flange. When the same type of chromium stainless steel flange welding rod is used, preheating above 200 ℃ and tempering treatment at 800 ℃ after welding shall be carried out. If the weldment cannot be heat treated, stainless steel flange pipe welding rod shall be selected.

4、 Stainless steel flange pipe fittings, butt welding flange electrode has good corrosion resistance and oxidation resistance, widely used in chemical industry, chemical fertilizer, petroleum, medical machinery manufacturing.

5、 In order to prevent eye to eye corrosion caused by flange cover heating, the welding current should not be too large, about 20% less than that of carbon steel electrode, the arc should not be too long, the interlayer should be cooled quickly, and the narrow weld bead is suitable.

6、 After welding, the hardening American standard flange of chromium stainless steel flange pipe is large and easy to crack. If the same type of chromium stainless steel electrode is used for welding, preheating above 300 ℃ and slow cooling treatment at 700 ℃ after welding must be carried out. If post weld heat treatment is not available for weldment, stainless steel flange pipe welding rod shall be selected.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: