A flange is a pipe-to-pipe connection that attaches to the end of a pipe. There are holes in the flanges that can be screwed on so that the two flanges are tightly connected. Flange connections consist of a pair of flanges, a washer and several bolts and nuts. Gaskets are placed between the sealing surfaces of the two flanges. After the nut is tightened, the washer consists of a washer, a washer and several bolts and nuts.

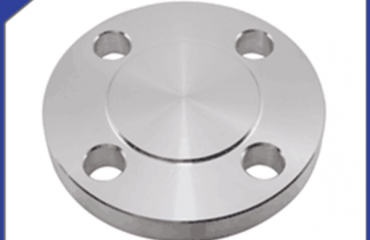

According to the connection method between the flange and the pipeline, it is divided into: flat welding flange with neck, socket welding flange with neck, flat welding flange, type A butt welding ring plate loose flange, B type butt welding ring plate loose flange Sleeve flange, integral flange, threaded flange with neck, butt welding flange, flat welding ring plate loose flange, pipe end flanging plate loose flange (type A), flanging short plate loose method Flange (type B) and flange cover (also known as blind flange), etc.

Threaded flange is a non-welded flange. Compared with welded flange, threaded flange has the characteristics of convenient installation and maintenance. It can be used on some pipelines that are not allowed to be welded on site. Alloy steel flanges have sufficient Strong strength, but not easy to weld, or poor welding performance, threaded flanges can also be used. However, in the case of rapid changes in pipeline temperature or when the temperature is higher than 260 °C or lower than -45 °C, it is recommended not to use threaded flanges to avoid A leak has occurred.

Butt welding flange, also known as high neck flange, is different from other flanges in that there is a long and inclined high neck from the welding point of the flange and the pipe to the flange, and the wall thickness of this high neck is along the height. The direction gradually transitions to the thickness of the pipe wall, thereby improving the discontinuity of stress, thereby increasing the strength of the flange, butt welding flanges are mainly used in harsh working conditions.

The flat welding flange is also called the lap welding flange. The connection between the flat welding flange and the pipe is to first place the inner hole of the pipe flange to the appropriate position, and then weld it. The advantage is that it is easier to align during welding and assembly, and the price Low cost, so it has been widely used. According to the internal pressure calculation, the strength of the flat welding flange is about 2/3 of the butt welding flange, and the fatigue life is about 1/3 of the butt welding flange. Therefore, the flat welding method The flange is only suitable for pipeline systems with low pressure levels and low pressure fluctuations and vibrations.

The above is the basic knowledge sharing of some flange products.

Language

Language Espanol

Espanol English

English Italian

Italian عربى

عربى

Skype: chinamaker99

Skype: chinamaker99  Tel: 86-316-5120812

Tel: 86-316-5120812 Email:

Email:  Whatsapp:

Whatsapp: